The popularity of 3D printing has had a major impact on advancements in research within the medical industry. Although scientists have not yet found a 3D printed material to perfectly replicate bone, a research team has recently created a new bio-glass substance that can be custom printed to replace damaged cartilage. Developed by researchers at Imperial College London and the University of Milano-Bicocca, this bio-glass is able to duplicate all the properties of real cartilage, while also promoting the re-growth of natural cartilage.

The popularity of 3D printing has had a major impact on advancements in research within the medical industry. Although scientists have not yet found a 3D printed material to perfectly replicate bone, a research team has recently created a new bio-glass substance that can be custom printed to replace damaged cartilage. Developed by researchers at Imperial College London and the University of Milano-Bicocca, this bio-glass is able to duplicate all the properties of real cartilage, while also promoting the re-growth of natural cartilage.

Cartilage, a firm connective tissue found in joints and spine vertebrae, is much softer and flexible than bone. It is not easy to repair and its degeneration can cause severe pain for patients who experience it. In order to repair this tissue, doctors require a material that qualities and texture that are almost identical to real cartilage, which is exactly what this bio-glass offers.

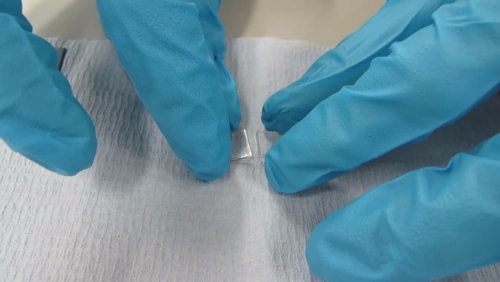

Made from polycaprolactone mixed with silica, the bio-material has both strong and flexible qualities, along with the same load bearing and shock absorbent properties as cartilage. Furthermore, bio-glass plus contains self-healing properties allowing it to reconnect if pulled apart. The material can be produced in biodegradable ink form which allows it to be 3D printed to fit the exact specifications of the patient.

Bio-glass could have numerous uses in the future, including implants for patients with damaged discs or printed supports to replicate lost knee cartilage. These printed supports would encourage damaged cartilage to grow through the bio-material before it degrades, replacing the printed area with healthy new cartilage.

Medical advancements, like bio-glass, are vital in the health sciences industry to ensure the best care is given to individuals who need it. Whether you require prototype systems to surgical devices and tools, Eclipse understands the need for medical suppliers to offer the highest quality of products that increase patient safety and ensure compliance.

Source: Gizmag