Printable electronics may be more simple and affordable to manufacture, but are so delicate that their shelf life negates any savings that might be gained.

Printable electronics may be more simple and affordable to manufacture, but are so delicate that their shelf life negates any savings that might be gained.

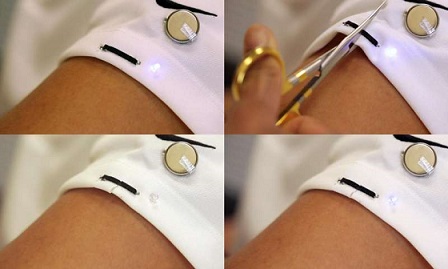

Researchers at the University of California San Diego (UCSD) have developed a new type of magnetic ink that produces electronic devices with self-healing capabilities. Researchers believe this self-healing quality will make printed electronics far more robust, thus more practical for a number of new applications.

This self-healing material is capable of repairing tears as wide as three millimeters in 50 milliseconds, whereas other healing materials can take minutes to days to repair. The self-healing quality is due to microparticles that orient themselves in a particular way when in the presence of a magnetic field. Unlike other self-healing materials, it does not require an external force to trigger the self-healing process.

Researchers had to overcome was the magnetic field of the particles canceling each other out and to do so, it required another magnetic field. When the magnetic ink was printed in the form of a circuit, it was done in the presence of another magnetic field, which made the particles orient themselves as a permanent magnet at the two polar ends of the printed device. With one end positive and the other negative, the two magnets attract each other when divided into two parts.

This type of new technology could be the future of wearable and printed electronics primarily for batteries and sensors. Eclipse Automation stays flexible in its ability to find the most integrated innovative solutions that add client value and enhance business operations, especially in pioneering electronic markets.

Source: IEEE Spectrum