INNOVATIVE

NUCLEAR-ENGINEERED AUTOMATION SOLUTIONS

THANK YOU FOR YOUR INTEREST IN OUR SMART AUTOMATION SOLUTIONS FOR THE NUCLEAR INDUSTRY

Below you will find more information about our extensive work within the nuclear industry. Please reach out to our Eclipse nuclear team, contact details at the bottom of this page, for more details about our wide range of services.

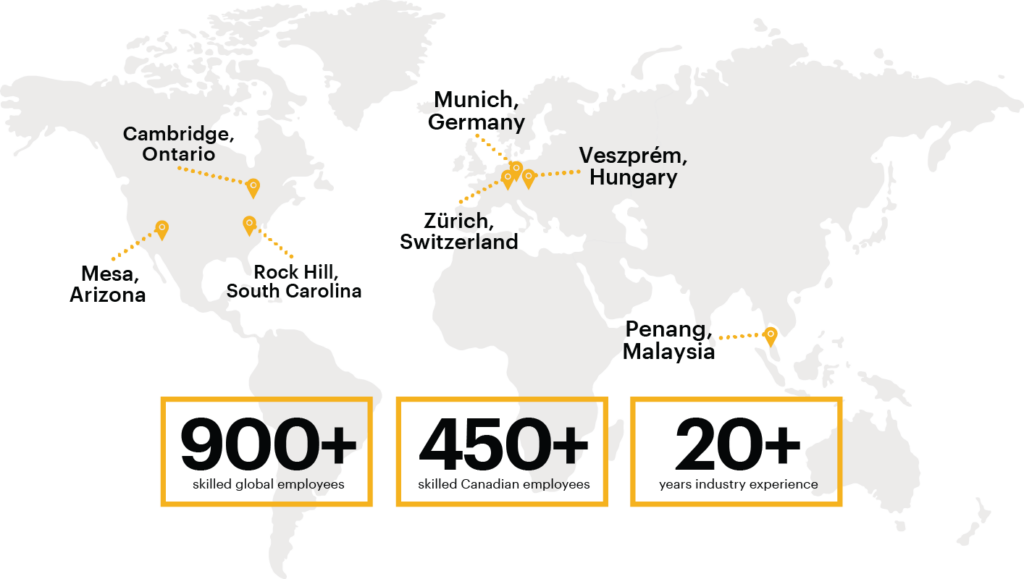

We Are Powered by Local Expertise & Global Experience

Our Goal for Nuclear Clients

Our goal is to design and build the future through innovative automation systems that can make nuclear energy even better, safer and more sustainable.

Eclipse has delivered smart solutions in:

Nuclear Energy Solutions

Why Partner with Eclipse?

- We are fluent in nuclear power, we’ve built a division solely dedicated to the industry, employing nuclear energy experts

- We combine complex know-how of production, manufacturing, and distribution of high-tech automated solutions with deep nuclear industry knowledge

- Clients include many of the world’s leading companies, who we help to develop efficient systems that accelerate their goals

- We have modified our successful, precision techniques and strategy to create safe, reliable, and cost-effective solutions for key nuclear clients

Some of Our Recent Projects

CANDU Refurbishments

Design, development, and supply of custom tooling for CANDU6, Bruce Power and OPG reactor refurbishments

Vertical Flux Detector Removal

Design, supply, and execution support of flux detector removal and volume reduction equipment, enabling medical isotope production in CANDU reactors at Bruce Power

CanAtom/OPG Installation Work Tables

Innovations to improve Calandria Tube Installation at Darlington

Whiteshell Decommissioning: Design & Build

First of a kind remotely controlled system to safely retrieve, sort and package radioactive waste for remediation of CNL’s Whiteshell Site

Whiteshell Decommissioning: ISOT

Full-scale outdoor mock-up facility in Cambridge for Integrated System Operations Testing and operator training on the Whiteshell decommissioning equipment

Advanced Nuclear Materials Research Centre

Design, manufacture, and test of prefabricated structures, components and remotely controlled systems for CNL’s state-of-the-art, multi-unit Hot Cell facility in Chalk River for R&D on radioactive materials and used fuel

Other Services

- Training Simulators and Services

- Digital Twin and Mixed Reality Simulations

- Process Storyboarding

- 3D Modelling and Simulations

- Plant Layout

- Concept Engineering

- Proof of Concept Development

- Reactivity Mechanism Removal and Volume Reduction

- Header Nozzle Machining, Welding, and Inspection

- Automated Lattice Site Inspection and CT Installation

ROMA Arm Demo

Strength in Collaboration

Eclipse Automation is proud to be a part of Accenture – combining a powerful set of skills and technologies for our clients.

Artificial Intelligence: AI can hone system performance with applications for condition monitoring and predictive maintenance

Industrial Robotics: The use of Cobots, computer-controlled robotic devices designed to assist a person, can mitigate risk and accelerate performance

Special Tools: Automated Flaw/Non-Destructive Examination (NDE) Analysis and Custom Document Management tools can apply the latest digital resources to a system

Sustainability: Industry 4.0 adoption has encouraged internal and external sustainability practices to be integral to the plan