Create a revolution with Smart Factory automation

In the era of Industry 4.0, the manufacturing landscape is undergoing a transformative revolution with the advent of Smart Factories. These high-tech production facilities combine the power of advanced automation, artificial intelligence, and data analytics to create an interconnected and intelligent manufacturing environment. At the heart of this evolution lies the critical role of industrial automation solutions in reshaping the future of manufacturing.

Unlocking unprecedented efficiency and productivity

Industrial automation is the driving force behind the remarkable efficiency achieved in Smart Factories. Automated systems and robotic solutions streamline repetitive tasks, allowing human workers to focus on higher-value activities that require creativity, problem-solving, and innovation. This seamless collaboration between humans and machines underpins the concept of Industry 4.0, where technology enhances human capabilities and creates a more harmonious and productive work environment.

With real-time data collection and analysis, Smart Factories can optimize production processes and adapt swiftly to changing demands. This level of flexibility and responsiveness leads to reduced downtime, minimized waste, and optimized resource utilization, ultimately translating into increased productivity and enhanced profitability.

Aiding the design and build of Smart Factories

The team at Eclipse Automation, with expertise in smart manufacturing plays a pivotal role in aiding the design and build of Smart Factories. From the conceptualization stage to full-scale implementation, an experienced automation partner can offer invaluable support:

- Customized solutions: Eclipse can tailor solutions to meet the unique needs of each Smart Factory, ensuring maximum efficiency and productivity gains.

- Expert consultation: our experts can provide valuable insights into the latest technologies and best practices, helping manufacturers make informed decisions.

- Seamless integration: our specialists can seamlessly integrate new automation systems with existing equipment, ensuring a smooth transition to a Smart Factory setup.

- Comprehensive training and support: we offer training and support to empower factory personnel to work efficiently with new technologies and systems.

- Continuous improvement: Through proactive maintenance and continuous optimization, automation partners help Smart Factories stay at the forefront of Industry 4.0 advancements.

Partner with Eclipse Automation for Smart Factory success

At Eclipse Automation we are passionate about driving the transformation of traditional manufacturing into Smart Factories of the future. Our state-of-the-art industrial automation solutions empower businesses to embrace Industry 4.0 and unlock unparalleled efficiency, productivity, and innovation.

Contact us today to explore how our expertise can aid the design and build of your Smart Factory. Together, let’s embrace the future of manufacturing and embark on a journey of unprecedented success.

Data systems –

Shop floor to top floor

Access to real-time data throughout your manufacturing operation can many advantages including:

- Enhanced product traceability

- Operation performance visibility

- Ability to react faster to changing demands

- Improved system security

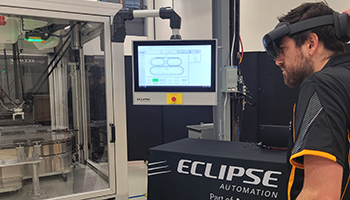

Virtual Reality (VR)/Augmented Reality (AR)

As AR and VR technologies have matured, Eclipse has realized the practical application of these technologies for industrial automated manufacturing.

A few of the practical applications being deployed today are:

- Collaborative design reviews via Omiverse

- VR design and ergonomics checking

- AR internal support across departments and locations via HoloLens 2

- Customer support

- Customer operator and maintenance training

Digital twinning

Through creation of a digital twin of an automated manufacturing process, many benefits can be realized to save time and cost. There are many levels of digital twin available and Eclipse is at the forefront of utilizing this technology.

Some of the practical applications utilized include:

- Kinematics simulation

- Mechanical design validation

- Process validation

- Early manufacturing process validation for faster product launch and higher production quality

- Robotic path creation

- Ensure safety, avoid costly mistakes, estimate cycle time.

- User standards and advanced robotics

- Increase efficiency by standardization, re-use and automatic robot program generation.

- Virtual commissioning

- Reduce risk and accelerate integration by validating PLC and robot code, control signals prior to full commissioning.

- Virtual Reality

- Enhanced experience for team and client collaboration and validation. Reduce cost and risk for travelling and training.