Philip Neal, US General Manager

When manufacturers think about product traceability, they’re often envisioning a worst-case scenario: a recall notice, a regulatory investigation, or a frantic effort to identify which products need to be pulled from shelves. For decades, traceability has been viewed as an insurance policy, necessary for compliance — especially in highly regulated industries like pharmaceuticals and nuclear — but primarily a cost center, focused on damage control after problems occur.

That reactive mindset is rapidly becoming obsolete.

In this article

- Traditional product traceability focused on regulatory compliance while post-incident response is evolving into predictive error prevention systems.

- AI-powered vision systems and automated factory lines can now learn from traceability data to prevent common manufacturing errors before they occur.

- Industries from automotive batteries to food production are discovering that smart traceability delivers significant ROI through waste reduction and quality improvement.

- Forward-thinking manufacturers are using real-time data analysis to transform traceability from a compliance cost center into a competitive advantage.

The smart traceability revolution

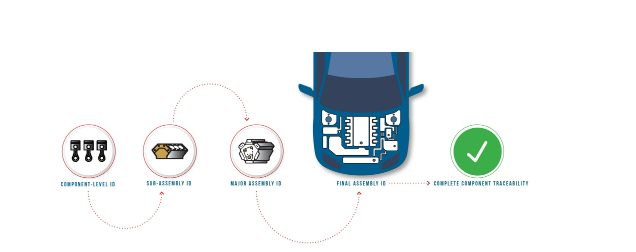

According to MECCO, a leading provider of industrial product marking and identification systems, traceability is “the process for locating components and their appropriate history throughout their life.” At its most basic, this means marking parts with a permanent serial number or other unique identifier (UID), allowing the part to be identified throughout production, and even out into the field, post-purchase.

These days, though, traceability can go much further. Individual components can be marked as soon as they’re manufactured, allowing them to be digitally connected to a subassembly, a major assembly, and a final assembly.

Using this kind of fine-grained identification, today’s most innovative manufacturers are using traceability to do far more than simply track products in case of a recall. They’re also using the rich data streams coming from their sensor-packed factories to identify error patterns. They then program these insights into AI-powered vision systems and automated production lines, helping to prevent defects from happening in the first place.

The results can be transformative. According to a 2021 study by the World Economic Forum,

“Companies that build robust traceability will be able to meet their sustainability targets, stakeholder demands and new regulatory requirements. They also will be able to deliver the right product to the right place at the right time and with the right level of customization and speed – all at a competitive cost.”

More importantly, they’re discovering that the same systems designed for regulatory compliance can deliver substantial competitive advantages through predictive quality control.

Consider as an example a manufacturer of automotive batteries, tracking every component through production. Traditional tracing practices would simply log the materials going into each battery. But by analyzing the tracing data, the factory identifies that batteries produced on Tuesday afternoons show 15% higher failure rates. Further analysis reveals the pattern correlates with a specific supplier’s delivery schedule and storage temperature variations. The manufacturer can now automatically adjust production parameters or flag materials for additional inspection, preventing defective batteries from ever reaching customers.

From pharmaceuticals to food: Expanding applications

Life sciences companies have long embraced comprehensive traceability, tracking everything from raw material sources to individual tablet serialization, largely out of necessity brought on by rigorous certification schemes. More recently, though, other industries have been catching up, as they recognize the broader value proposition.

Food traceability is a good example. In food manufacturing, companies are moving beyond basic lot tracking to implement real-time monitoring that can predict contamination risks. Sensors throughout the supply chain feed data into AI models that learn to identify environmental conditions, supplier patterns, and processing parameters associated with quality issues.

Electronics manufacturers face unique challenges with over 100 discrete manufacturing steps in complex products like semiconductors. Smart traceability systems can analyze correlations between component suppliers, assembly conditions, and field failure rates to optimize supplier selection and production parameters.

Sporting goods companies are discovering that traceability extends their value proposition beyond manufacturing. A premium bicycle manufacturer, for instance, could provide customers with complete provenance information: which vendor supplied the carbon fiber, which facility performed the layup, even which technician assembled the final product. This transparency builds brand trust in high-performance products, while enabling rapid response to any quality issues.

In each of these examples, the shift is toward pro-active quality control. Instead of waiting for customer complaints or regulatory inspections, these systems can automatically adjust processing conditions or flag shipments for additional testing.

Nuclear-level precision for mainstream manufacturing

The nuclear industry, because of its extreme requirements for reliability and transparency, offers a glimpse into smart tracing’s ultimate potential. Every component in a nuclear facility requires complete documentation of materials, manufacturing processes, quality inspections, and installation procedures. If an issue arises, operators can immediately identify every related component that might be affected. This level of precision prevents small problems from cascading into catastrophic failures.

Mainstream manufacturers are adapting these principles to their own operations. While a consumer electronics company might not face nuclear-level safety risks, the economic logic is similar: comprehensive traceability enables targeted responses that protect brand reputation and minimize financial exposure.

Looking forward: The competitive imperative

The financial case for smart traceability is compelling when you view it through the lens of problem prevention rather than just compliance. The “1-10-100 rule” states that fixing defects during production costs 10x more than preventing them during design, while post-delivery fixes can cost 100x more than early prevention.

The broader business benefits compound over time. Companies with robust traceability can use it to enhance customer trust and create premium pricing opportunities for verified authentic products, while significantly reducing warranty claims and recall costs. And as AI and IoT technologies mature, the gap between companies with smart traceability and those relying on traditional approaches will widen.

The spectre of recalls and failed products will never go away, of course. But with powerful data-gathering, analysis, and product-tracing tools becoming more available and less expensive, it’s time to look further.

Curious to learn more about implementing smart traceability systems that prevent errors while ensuring compliance? Discover how Eclipse’s automation integration services can transform your manufacturing operations through predictive quality control and comprehensive supply chain visibility.

Get in touch to explore how our Advanced Engineering Services can help you move faster without compromising results.