Winding Technology by Eclipse Automation Switzerland

Eclipse Automation Switzerland is a global leader in production solutions for electric motors.

Our long history of Swiss competence in Winding Technology dates back more than 100 years.

The latest Coil Winding Technology

For our customers, we take on overall responsibility for cost-optimized and reliable electric motor production solutions with the focus on short market introduction cycles.

The team at Eclipse Switzerland accompanies you from the development and industrialization concept stages through to the finished system solution.

We construct winding machinery and equipment for the manufacture of a wide range of electric motors and offer you production security through our comprehensive service.

We are a dynamic partner with creative and proven solutions.

Core competencies

- Expertise in all Winding Technologies

-

Leading-edge in-house production methods

- Technical verification of electric motor production concepts with prototypes and small production runs

- Innovative and high-quality production solutions

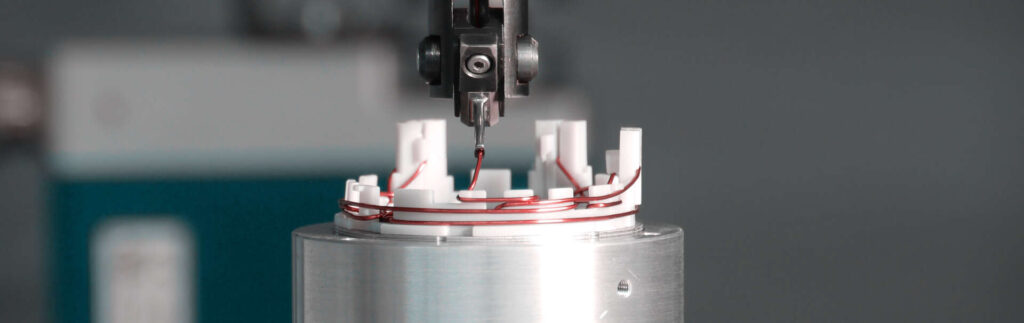

Needle Winding Machine and Technology

The centerpiece of electric motor winding is our automatic needle winding machine, which can wind inside or outside slotted stators and thus offers the highest flexibility with the lowest investment.

Additional technical highlights

- High fill factor through layer winding

- Concentrated or distributed winding

- Adaptive loading and unloading concepts

- Synchronous axis control

- Automatic contacting

- Skewed slotted winding possible

- Flexible set-up enables easy retooling

- Interconnect directly in the winding process

- Possibility of winding parallel wires

- Low tooling costs for additional types

- Custom nozzle design for careful wire handling

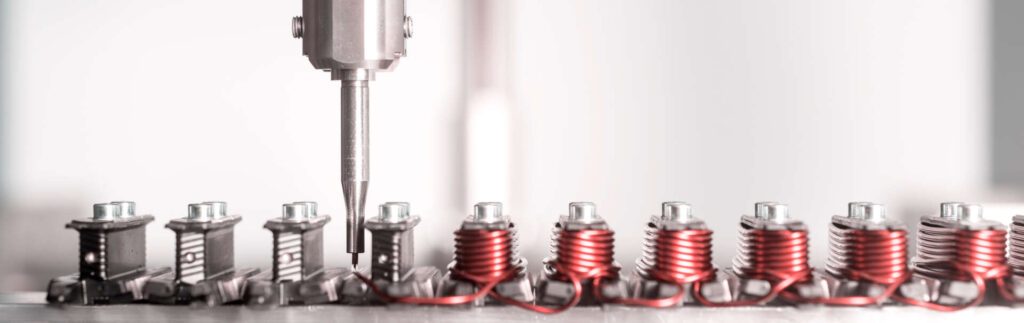

Linear Winding Technology

The centerpiece of winding tooth chains is our linear winding machine, which can wind open stators or linear motors in a very wide range of stack designs as well as wire diameters and therefore offers the highest flexibility with the lowest investment.

Additional technical highlights

- Precise and tight-fitting wire guidance, especially suitable for large wire diameters

- High fill factor through layer winding

- Adaptive loading and unloading concepts

- Synchronous axis control

- Automatic contacting

- Flexible set-up enables easy retooling

- Interconnect directly in the winding process

- No bulging of the winding

- Custom nozzle design for careful wire handling

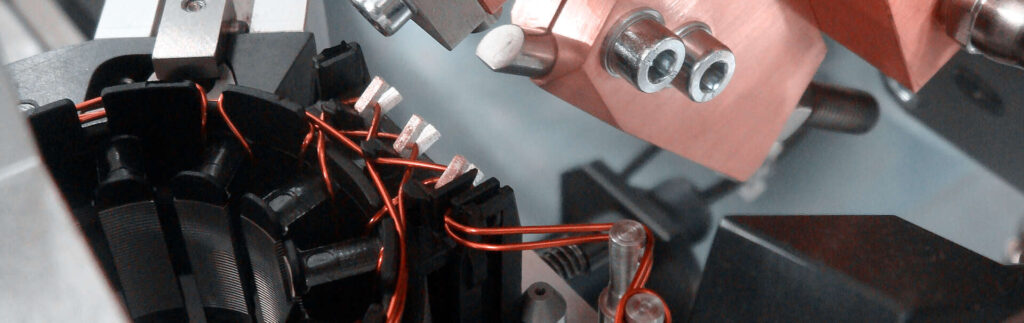

Coil Winding Technology

Coil winding technology is another popular Winding Technology process that we have perfected.

Our coil winding machines are distinguished by their precise wire guidance and exact monitoring of the wire drawing settings.

Additional technical highlights

- Modular concept with single or multiple winding stations

- Wire cutting system

- Adaptive loading and unloading concepts

- Low tooling costs for additional types

- Custom nozzle design for careful wire handling

Contact and coil welding technology

We have expert knowledge in various contacting technologies. Our engineers select the best for you.

A well-functioning contacting and welding technology is the prerequisite for a successful and swift production process.

We supply the necessary know-how and the appropriate solutions.

Resistance coil welding technology

We have been using this process for years and will advise you in all associated matters to do with resistance, thermos-compression, ultrasound and laser welding technology. Our equipment contacts precisely and has high-quality, robust in-house developed welding heads with the best pressing performance.

Insulation displacement technology

Our engineers have many years of application expertise in the area of insulation displacement contact technology. We maintain stable partnerships with well-known equipment manufacturers and integrate their components seamlessly into our overall system.

Soldering contact technology

With this winding technology we use soldering heads controlled by robotics with precise guidance of the solder wire, with which the contact is soldered with pinpoint accuracy. We integrate this equipment with the electric motors production facility.

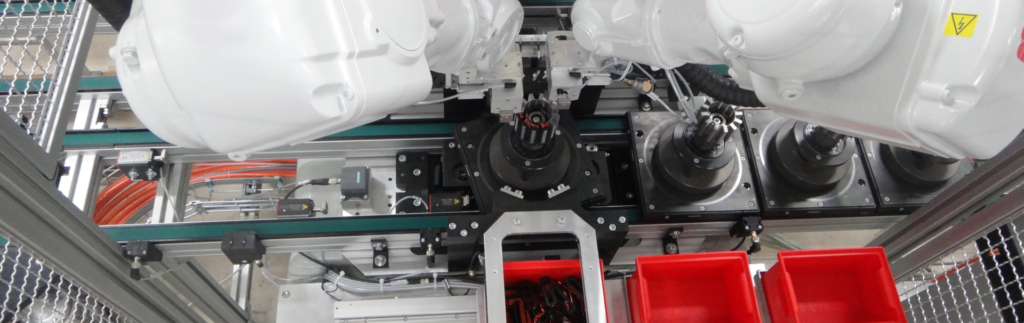

Assembly technology

We build standardized and tailor-made assembly systems for customer-specific requirements. We combine our electric motors production solutions with highly standardized and tailor-made assembly systems such as flexible part feed systems, robot integrations, automatic joining machines, test cells, and palletizers.

Benefits

- Full-range supplier of electric motor winding and assembly solutions

- Small utility spaces combined with high-flexibility and complex processes

- Precision matched with the desired accuracy to lower maintenance costs

We provide support at every stage of development