In today’s fast-moving industrial landscape, staying competitive means embracing innovation—and at the heart of that transformation is assembly line automation. If your production line hasn’t yet adopted automation technologies, now is the time. Below, we break down the top reasons why smart manufacturers are turning to automation solutions to lead the future of Industry 4.0.

Boost manufacturing productivity with automation

Automating your assembly line is one of the fastest ways to increase output without increasing labor costs. Machines can operate 24/7 with minimal downtime, delivering unmatched consistency and throughput.

With Eclipse Automation’s scalable automation systems, manufacturers gain real-time visibility, faster cycle times, and the ability to meet market demand with speed and agility—critical in competitive sectors like automotive, life sciences, and consumer goods. Automating assembly lines dramatically increases productivity, allowing machines to perform tasks quicker and more accurately than human workers. Plus, machines don’t need breaks, and they don’t sleep—therefore, running assembly lines 24/7 becomes a viable, more cost-effective option. If you’re looking for a massive surge in efficiency and output, the automation revolution offers it.

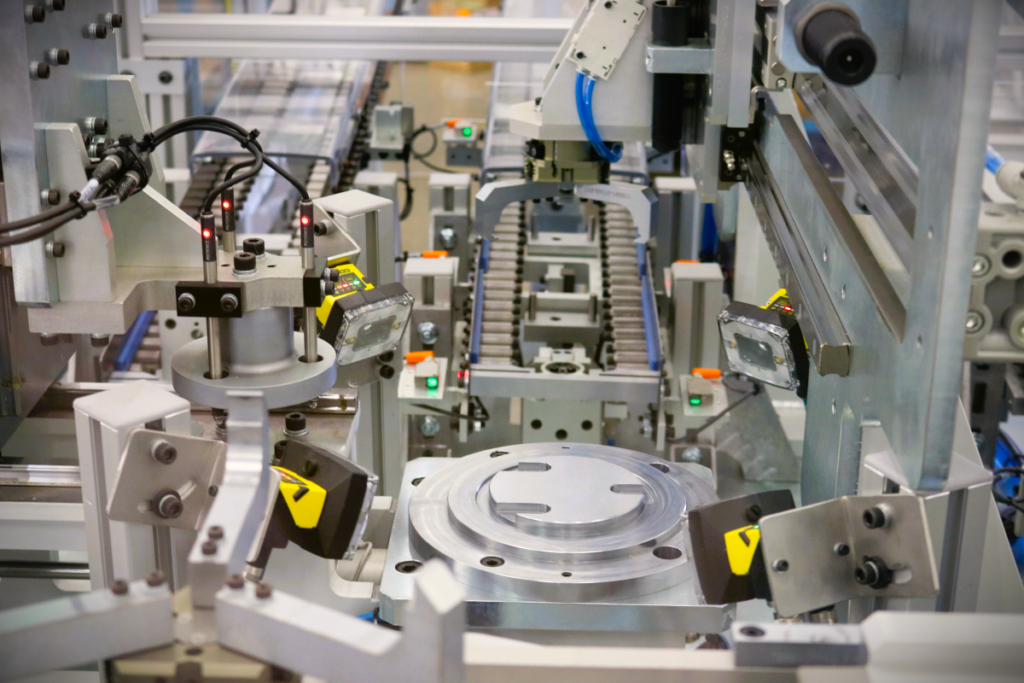

Improve product quality and repeatability

Automated assembly ensures precise, repeatable tasks—every time. By eliminating variability and reducing human error, automation enhances product quality, especially in high-precision industries like medical devices, EV battery production, and aerospace manufacturing.

Automated systems maintain consistent precision and eliminate human errors in the areas of exquisite workmanship and top-notch quality assurance, especially when it comes to custom automation in the automotive and transportation industries. Automation in these industries helps companies deliver products of unparalleled quality—every single time, making it one of the best reasons to automate your assembly lines. It’s fascinating to consider the enormous impact automation could have on your customer service and sales goals.

Reducing operational costs and waster

While there’s an upfront investment in industrial automation, the long-term savings are significant. Automated lines reduce labor expenses, minimize rework, and decrease raw material waste.

Our custom-engineered automation solutions are optimized for both performance and efficiency—delivering lower cost per part and a fast ROI across production environments.

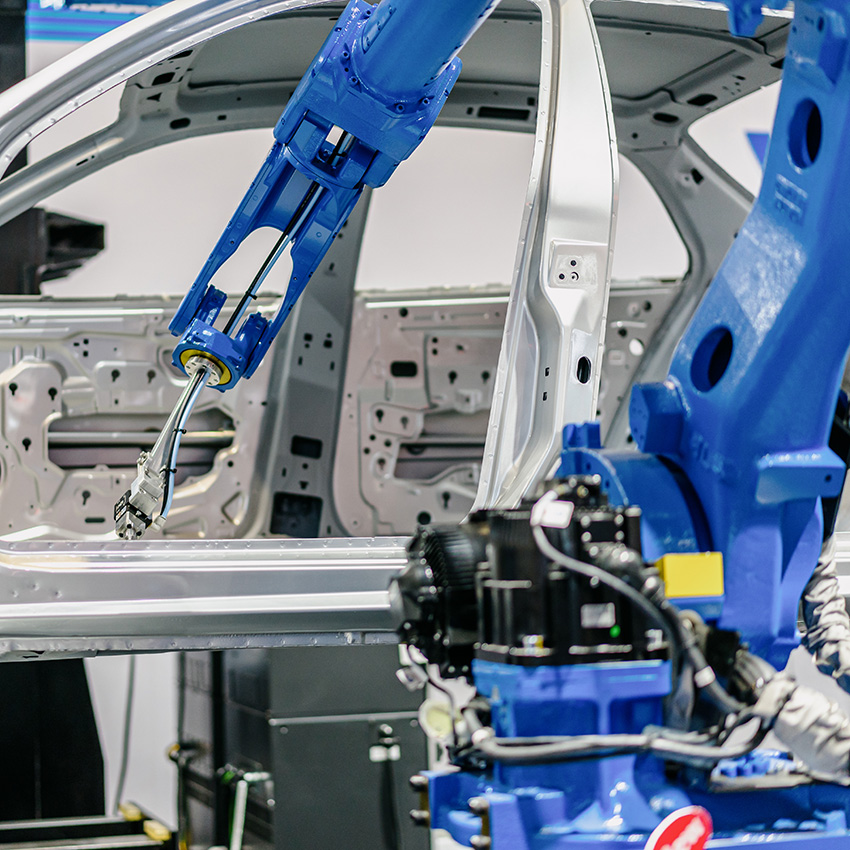

Enhance workplace safety and employee satisfaction

Automation doesn’t replace people—it empowers them. By shifting repetitive or hazardous tasks to machines, manufacturers reduce workplace injuries and improve job satisfaction.

Employees can transition to higher-value roles in quality assurance, maintenance, or innovation, while automation handles the physically demanding work. It’s a win for safety, productivity, and team morale. The result is a happier, healthier workforce that can focus on more engaging tasks, like quality control and innovation. By embracing the myriad advantages of automation, you will significantly reduce the likelihood of workplace injuries.

Stay ahead with future-ready automation technology

Assembly line automation is not a trend—it’s a foundational element of smart manufacturing and Industry 4.0. Companies that invest now will benefit from agile, connected systems that evolve with product complexity and market demands.

With decades of experience across automotive, life sciences, electronics, and advanced manufacturing, Eclipse Automation is a global leader in building intelligent, scalable assembly systems. Our end-to-end approach—from concept and design to integration and support—ensures your automation delivers long-term value.