5 reasons to automate your assembly lines

Automation is becoming a crucial aspect of almost every assembly line. If you haven’t embraced it yet, here are some reasons to consider implementing it.

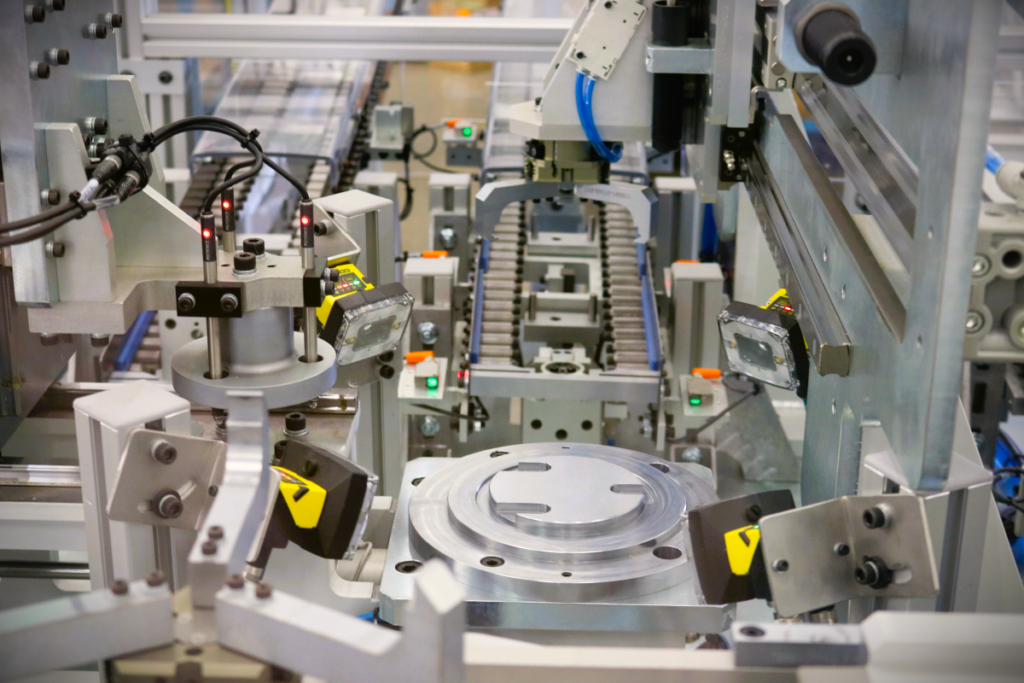

Picture this: a factory buzzing with innovative machines, working at breakneck speeds, turning raw materials into groundbreaking products that propel your business forward. Sounds like a dream, doesn’t it? Well, it doesn’t have to be.

In today’s fast-paced world, gaining a competitive edge in the dynamic manufacturing landscape is crucial. And there’s no better way to achieve that than by embracing automation. Here are some reasons why you should automate your assembly lines and begin reaping the benefits of this remarkable technology.

Boost productivity

Automating assembly lines dramatically increases productivity, allowing machines to perform tasks quicker and more accurately than human workers. Plus, machines don’t need breaks, and they don’t sleep—therefore, running assembly lines 24/7 becomes a viable, more cost-effective option. If you’re looking for a massive surge in efficiency and output, the automation revolution offers it.

Delivering unwavering quality

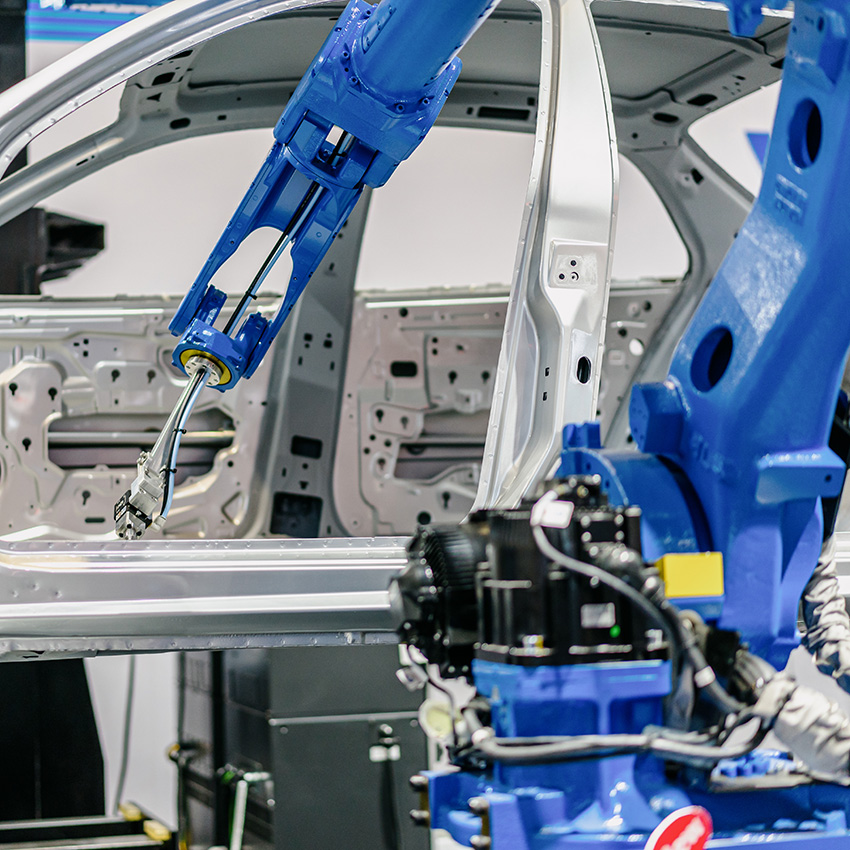

Automated systems maintain consistent precision and eliminate human errors in the areas of exquisite workmanship and top-notch quality assurance, especially when it comes to custom automation in the automotive and transportation industries. Automation in these industries helps companies deliver products of unparalleled quality—every single time, making it one of the best reasons to automate your assembly lines. It’s fascinating to consider the enormous impact automation could have on your customer service and sales goals.

Reducing operational costs

While the initial investment in automation equipment might seem substantial, the long-term rewards are worth every penny. With machines taking over laborious and repetitive tasks, the cost of human labour drops significantly. Moreover, the increased speed and accuracy of automated systems lead to a decrease in waste materials. It’s a win-win situation: enhancing your bottom line while ushering in a new era of manufacturing efficiency.

Worker safety and satisfaction

Though people worry about automation taking our jobs, human workers are not machines. The repetitive nature of some assembly line tasks can take a toll on our bodies. It’s better for machines to take over these repetitive, debilitating tasks in the long run, allowing people to fill more meaningful roles.

The result is a happier, healthier workforce that can focus on more engaging tasks, like quality control and innovation. By embracing the myriad advantages of automation, you will significantly reduce the likelihood of workplace injuries.

Future-proof your business

Finally, it’s essential to understand that automation is not just a passing trend—it’s been around for decades, and it’s here to stay. Companies that adopt advanced automation solutions will attract the brightest talents and evolve with market demands. By overlooking automation and hesitating to implement this game-changing technology, your business could risk getting lost in the shadows of its more visionary competitors.