How to ensure your business stays on the leading edge

With each passing year, the advancements made in the world of automation exceed what many thought was possible. This is especially true in the medical device manufacturing sector, an area where automation has been commonly used for years. That means you’re missing out if your business produces goods, but you haven’t switched to modern automated machine solutions yet.

If you want to know how automation can benefit medical device producers, this post is here to review the basics for you. That way, you can determine if the switch to automation is right for you.

Precision and consistency:

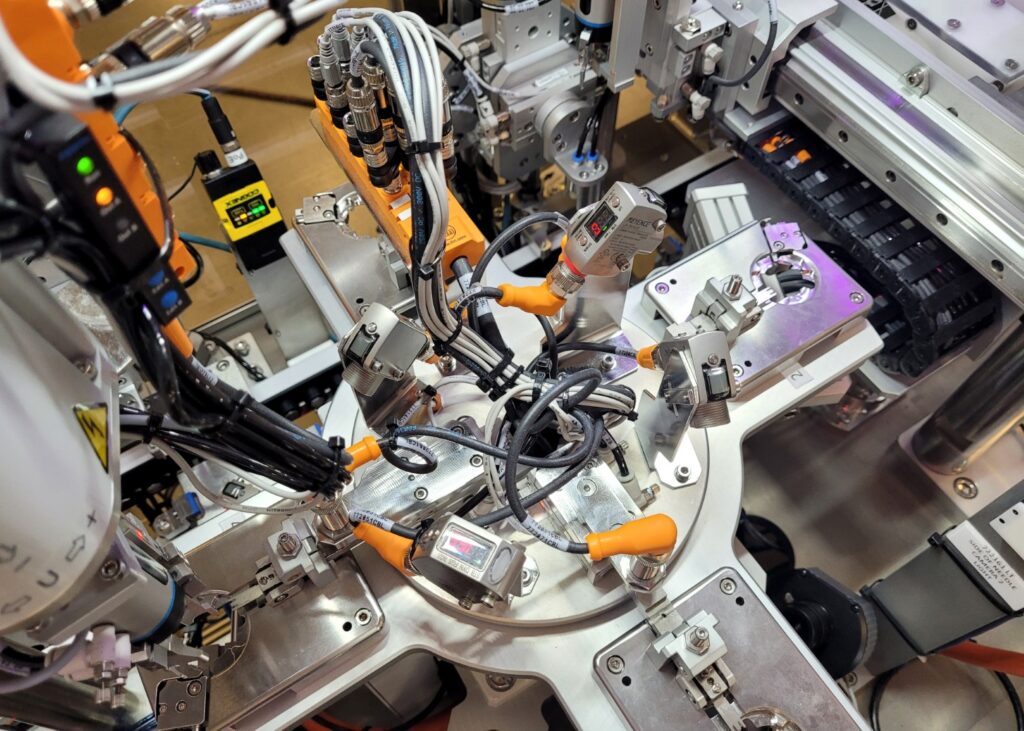

Industrial automation ensures unparalleled precision in the production of medical devices. Automated systems can perform intricate tasks with accuracy, reducing the margin of error that may arise from manual processes. Consistency in manufacturing is crucial for medical devices, where precision can be a matter of life and death.

Increased production speed:

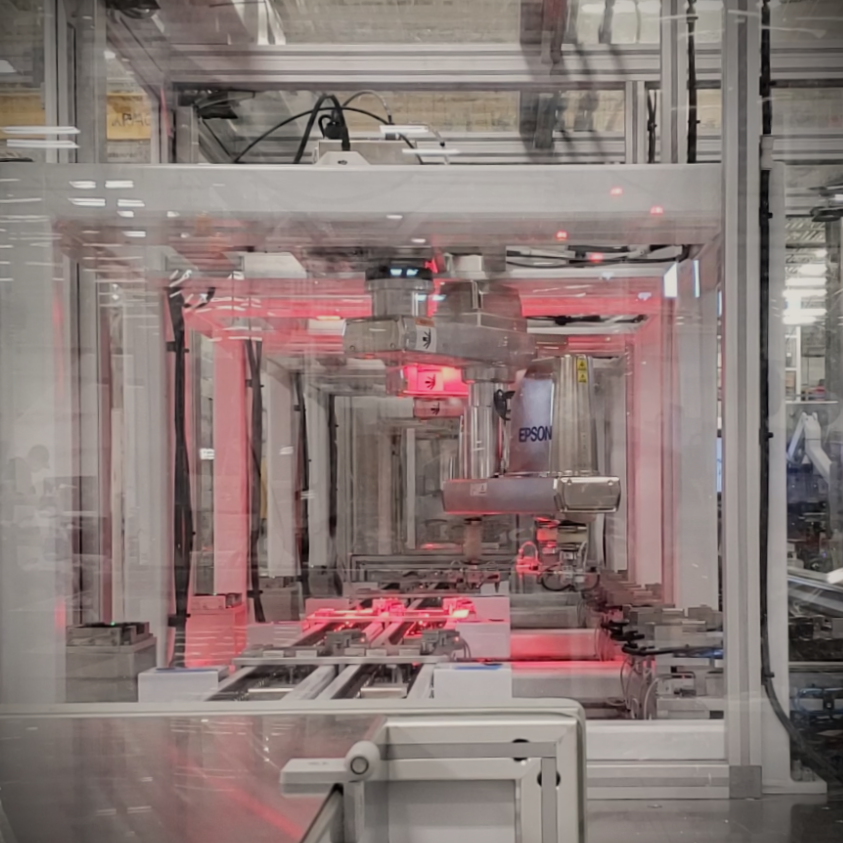

Automated production lines operate at higher speeds compared to manual processes. This acceleration in production speed allows for a more rapid response to market demands, ensuring that medical devices are manufactured and delivered in a timely manner. This is particularly crucial in situations where there is a sudden surge in demand, such as during public health emergencies like the recent pandemic.

Cost efficiency:

While the initial investment in automation technology may be significant, the long-term cost savings are substantial. Automated systems can operate continuously, reducing the need for breaks and minimizing the risk of human error. This efficiency results in lower production costs, improved resource utilization, and a higher return on investment over time.

Quality control and compliance:

Maintaining stringent quality control is paramount in medical device production. Automated systems can incorporate advanced sensors and monitoring technologies to consistently assess product quality throughout the manufacturing process. This ensures that products meet regulatory standards, reducing the risk of defects, and ensuring compliance with industry regulations.

Flexibility and adaptability:

Industrial automation provides a level of flexibility that is crucial in the ever-evolving landscape of medical device production. Automated systems can be easily reconfigured to accommodate changes in product specifications or the introduction of new devices. This adaptability allows manufacturers to stay ahead in a competitive market.

Worker safety:

The medical device industry often involves the handling of delicate or hazardous materials. Automation reduces the exposure of workers to potential risks associated with manual handling. Robotic systems can perform tasks in environments that may be challenging or dangerous for humans, promoting a safer work environment.

Traceability and documentation:

Automated systems enable comprehensive traceability throughout the production process. Every step can be precisely documented, providing a transparent record of the manufacturing journey. This traceability is invaluable for quality assurance, regulatory compliance, and post-market surveillance.

Innovation and customization:

Automation can free human resources from routine tasks, allowing skilled professionals to focus on innovation and product development. This fosters a culture of continuous improvement and encourages the creation of cutting-edge medical devices that can address evolving health care needs.

24/7 operations:

Automated production lines can operate 24/7 without the need for breaks or shifts. This continuous operation maximizes efficiency and ensures a constant supply of medical devices, particularly critical in scenarios where demand is unpredictable or varies across different time zones.

Competitive edge:

Embracing industrial automation provides a significant competitive edge in the medical device industry. Manufacturers that invest in advanced technologies can respond more swiftly to market trends, innovate faster, and deliver high-quality products consistently, positioning themselves as leaders in the sector.

The advantages of industrial automation in medical device production are numerous, revolutionizing the way manufacturers approach innovation, precision, and efficiency. As the industry continues to evolve, automation will continue to play a pivotal role in shaping the future of medical device manufacturing, ensuring the delivery of cutting-edge, high-quality products to meet the ever-growing demands of the health care sector.