Alex Hume, Sales Account Manager, Life Sciences

Contract manufacturing (CM), where a client company contracts with an established manufacturer to make its product, has been growing dramatically in recent years. It brings obvious benefits in terms of reduced capital costs, gives instant access to existing expertise when entering a new field, and often provides economies of scale clients wouldn’t have in-house. But it’s in highly regulated industries like medical devices and pharmaceuticals that CM really shines: when the product you’ve designed faces a long and complex regulatory path to certification, an experienced vendor can be a godsend.

Getting value for money with a CM, however, is far from automatic. With less direct control over the manufacturing process, client companies can sometimes struggle to implement design changes, ramp up production, maintain quality control, or deal with supply chain hiccups. Protecting intellectual property also merits attention, especially if your product is being manufactured alongside those of your competitors.

For these reasons—and many others—it often makes sense to work closely with an experienced manufacturing automation integrator. An integrator can not only connect you with the right CM for your specific needs, but also create a roadmap for future expansion, ready to bring in the automation necessary to achieve your long-term volume goals a year or two down the line.

In this article

- Contract manufacturing (CM) is growing rapidly in popularity, especially in highly regulated industries such as pharma, medical devices, and aerospace.

- CM can offer several advantages: steering complex products through to certification, reducing shipping and regulatory costs, etc.

- Using a CM can bring challenges in protecting IP, maintaining quality control, scaling up production, among others.

- Working with an experienced automation integrator can streamline the CM process and mitigate many associated risks, through pre-engineering and detailed process planning.

Who’s using contract manufacturers?

A decade or two ago, contract manufacturing was largely used for churning out localized versions of mature products. Think Asahi Brewing contracting with Molson to produce its lager onsite in Canada, or Firestone manufacturing air suspension systems for BMWs in North America. The CM in this case is familiar with local regulations, suppliers, and logistical concerns, and local production often saves on shipping and importing costs—an area of renewed concern as tariffs start to stack up.

More recently, though, CMs have made their biggest gains in industries where regulatory compliance is a major consideration. ISO certification, especially for highly complex and critical products like Type III medical devices, is often the single biggest hurdle to clear for a new product. Building up the necessary expertise in-house can be extremely costly and time-consuming, making a seasoned CM an attractive option.

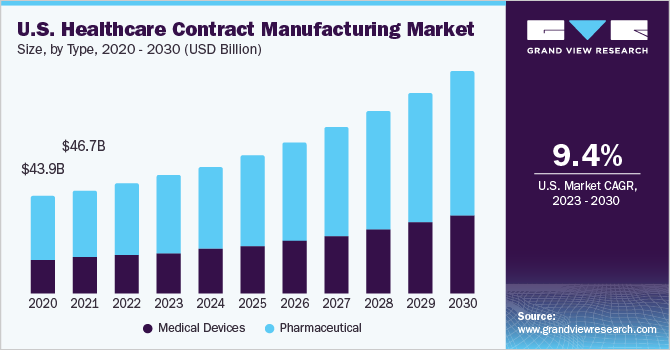

This helps explain why pharmaceutical companies now outsource more than two-thirds of their production, with medical device and aerospace manufacturers showing similar levels of contract reliance. Future growth is expected to continue at 9-10% per year.

Automotive manufacturers have long utilized CMs to handle the manufacture of specialized components like electronics and suspensions. But this too is being accelerated, in particular by the growing EV market. Today’s EVs require sophisticated new drivetrains, fuel cells, and batteries that an established automaker might lack the resources and know-how to build. At the same time, many of those components are very similar across EV types, making contract manufacturing an obvious solution.

What to watch out for

For all its popularity, and the many clear financial benefits it brings, contract manufacturing also introduces potential sources of complication, which require careful planning to mitigate.

Using a CM means moving production to a distant location, which means less direct oversight. This has implications for quality control, which must be more actively managed, especially if the product has high-precision components or criteria that must be met for certification. It helps to have very explicit guidelines and expectations set from early on, since “learning as you go” can be risky.

Especially when contracting with a manufacturer overseas, it’s also important to understand the differences in regulation and standards as far as intellectual property (IP) is concerned. A CM that specializes in a particular type of product—a specific category of medical device, for example—is likely to be manufacturing several of them at once, for different clients who may be your competitors. Having airtight legal agreements regarding what information can be shared, and what kinds of confidentiality and data management practices are in place, can go a long way toward avoiding future conflict, or even averting IP theft.

Finally, there’s the issue of scalability. A CM contract is typically for a set production volume, and the factory will build out or modify a line with an appropriate level of automation. A successful product, though, often translates into increased volume after a few years (or even months), and unlike in-house manufacturing, this is something that needs to be anticipated and mapped out in advance to avoid future bottlenecks.

The right integrator can make all the difference

While many companies may seek out a CM directly once the design for their product is set, it can often be useful to work with an automation integrator first. An established integrator will have a long list of trusted manufacturing partners, and years of experience managing production in collaboration with both clients and CMs. This can ultimately end up saving the client significant investment by identifying the right CM upfront, rather than risking a bad fit that leads to delays and cost overruns.

Even more important is the pre-automation support that an integrator can offer, often exceeding what the CM can. Eclipse’s Advanced Engineering Service (AES) helps both the CM and client with CapEx planning, providing detailed visualization services that allow everyone to see the production line in detail before a single robot is shipped. This makes design changes and production line refinements far cheaper and faster, and can help surface potential sources of delay—especially in highly regulated products—early in the planning process.

AES also includes a robust automation roadmap, which plans out not just the initial production line, but future expansions in line with anticipated volume growth. Clients and CMs both benefit from this kind of detailed foresight, which tends to pay for itself several times over when it comes time to ramp up.

So should your organization join the rising tide of CM production? It’s a complex question that involves many considerations, from the type of product you’re making, to the degree of regulation involved, to the physical location of production and expected volume. But regardless of your reasons for engaging a CM, talking to an experienced integrator early on could make all the difference.

Curious to learn more about how Eclipse’s industrial automation solutions and vertical integration approach can accelerate your next contract manufacturing project while maintaining exceptional quality standards? Get in touch to explore how our Advanced Engineering Services can help you move faster without compromising results.

Get in touch to explore how our Advanced Engineering Services can help you move faster without compromising results.