The importance of automation in the Life Sciences Industry

Without automation, the Life Sciences industry wouldn’t be nearly as far along as it is. Here, we explain what makes automation so crucial in this industry.

Technological advancements play a crucial role in shaping the future of healthcare in the fast-paced and ever-evolving world of Life Sciences and Medical Device solutions. One such innovation that has revolutionized the industry is custom industrial automation. By integrating automated systems into the medical industry, manufacturers can streamline processes, enhance productivity, and improve overall efficiency. In this article, we will explore the importance of custom automation in the Life Sciences industry and highlight its transformative impact on the production of medical devices and healthcare options.

We’ll explore why automation is so important in the Life Sciences field, and how this technology can help you stay ahead of your competition. Read on for details on how implementing custom industrial automation systems can drive growth within your business!

The benefits of industrial automation in the Life Sciences Industry:

Why it matters

The Life Sciences industry encompasses a wide range of disciplines, including pharmaceuticals, biotechnology, medical devices, and more. In this highly regulated and complex field, the role of custom industrial automation cannot be overstated. There are a few key reasons why industrial automation is so important in the Life Sciences industry.

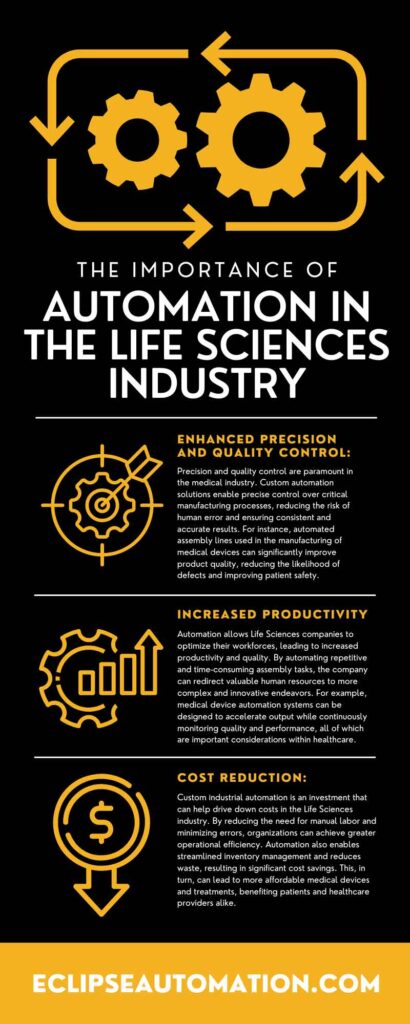

- Enhanced precision and quality control: Precision and quality control are paramount in the medical industry. Custom automation solutions enable precise control over critical manufacturing processes, reducing the risk of human error and ensuring consistent and accurate results. For instance, automated assembly lines used in the manufacturing of medical devices can significantly improve product quality, reducing the likelihood of defects and improving patient safety.

- Increased productivity: Automation allows Life Sciences companies to optimize their workforces, leading to increased productivity and quality. By automating repetitive and time-consuming assembly tasks, the company can redirect valuable human resources to more complex and innovative endeavors. For example, medical device automation systems can be designed to accelerate output while continuously monitoring quality and performance, all of which are important considerations within healthcare.

- Cost reduction: Custom industrial automation is an investment that can help drive down costs in the Life Sciences industry. By reducing the need for manual labour and minimizing errors, organizations can achieve greater operational efficiency. Automation also enables streamlined inventory management and reduces waste, resulting in significant cost savings. This, in turn, can lead to more affordable medical devices and treatments, benefitting patients and healthcare providers alike.

- Regulatory compliance and traceability: The manufacturing of healthcare devices requires strict adherence to regulatory standards and traceability requirements. Industrial automation aids in compliance by providing standardized processes and meticulous record-keeping. Automated systems can accurately track and document production parameters, test results, and component traceability, ensuring transparency and facilitating regulatory audits. This enhances product safety, regulatory compliance, and customer confidence.

- Speed to market: In the dynamic landscape of healthcare, speed to market is a critical factor when introducing new medical breakthroughs. The ability to swiftly bring innovative treatments, devices, and therapies to market has a profound impact on patient care, public health, and the competitiveness of the medical industry. Cutting-edge healthcare requires innovative manufacturing solutions in order to deliver on promises as quickly as possible. Speed to market allows companies to secure a competitive edge by capturing market share, establishing brand recognition, and generating revenue earlier than their competitors. Moreover, being at the forefront of medical breakthroughs enhances a company’s reputation as a leader in innovation, attracting investors, partnerships, and talent.

Examples of automation in the Life Sciences Industry

- Pharmaceutical manufacturing: Automation plays a vital role in pharmaceutical manufacturing, ensuring the production of high-quality medications. Customized automation systems can create complex packaging, monitoring, and delivery methods with unparalleled precision and accuracy. This eliminates variations in dosage, reduces contamination risks, and accelerates the manufacturing process, leading to faster availability of life-saving medications for patients worldwide.

- Innovative healthcare technologies: Automation has brought immense benefits to the rapid adoption of new life-enhancing and life-saving medical technologies through improved efficiency and scalability. High-tech manufacturing of the latest in point-of-care diagnostics, wearable health monitoring systems, medical test kits, and new surgical devices and tools have enabled advancements in personalized medicine and improved patient care. Maintaining quality is critical in the manufacturing of these medical devices, as automated systems can perform precise measurements, apply standardized assembly techniques, and conduct rigorous quality checks. This minimizes defects and ensures every product meets the specified standards, resulting in reliable and accurate diagnostic devices and tools that deliver consistent performance and enhance patient outcomes.

- Health food manufacturing: Automation can be a game-changer in regard to the increase in consumer demand for nutritious food and supplements. It can streamline production processes and ensure product quality, which is crucial in health food manufacturing. Automation plays a vital role in ensuring adherence to stringent quality control standards. Systems are capable of monitoring and regulating critical parameters such as temperature, humidity, and mixing ratios, minimizing the risk of human error and variations in product quality. Through real-time data monitoring and analysis, automation can detect deviations from desired specifications, allowing manufacturers to take corrective action. This level of precision and control contributes to producing safe and consistently high-quality products. Automation lines can also be reconfigured or programmed to accommodate new formulations and packaging options to adjust to rapidly evolving needs. Embracing automation will be essential for companies seeking to deliver nutritious, safe, and innovative products to a health-conscious consumer base.

What this means for the Life Sciences Industry

The advantages of automation in the Life Sciences industry are significant, which makes it so important. Custom industrial automation has become an indispensable tool in the Life Sciences industry, as it transforms the way medical devices are manufactured, treatments are administered, and people are supported in their healthcare journey. With enhanced precision, improved productivity, and long-term cost reduction, automation empowers organizations to deliver high-quality products and services while driving innovation in healthcare. As the medical industry continues to evolve, custom automation solutions will remain at the forefront, revolutionizing the field of Life Sciences and ultimately benefitting patients and healthcare providers around the world.

Incorporating custom automation of medical industry devices puts the industry in a prime position to unlock new frontiers in precision medicine, personalized healthcare, and improved patient outcomes. By harnessing the power of quality industrial automation in their manufacturing plans, Life Sciences organizations can shape a brighter future where technology and human expertise work in perfect synergy to advance the boundaries of medical science and make a meaningful impact on global health.