Turnkey solution offers design, build, test, transport, & assembly

The ask from the client was for a system that could safely retrieve, sort and package nuclear waste. Eclipse Automation stepped up, took over the design and provided a comprehensive and innovative solution that met the needs and more. The Eclipse team looked at the system holistically, not only designing the system, but also taking on manufacture/assembly, full scale integration testing, and training of the construction trades, as well as planning how to transport it, and how to move the 500-ton system around on site.

As the project evolved, the scope broadened because the team at Eclipse demonstrated their expertise and willingness to stretch to meet customer needs and project demands. They designed and built a full suite of equipment to deal with the waste that includes a Bunker Waste Retrieval System (BWRS), a Sorting and Conditioning Unit (SCU), Standpipe Headworks (SPH), and are taking responsibility to integrate a Standpipe Waste Removal System (SPWRS) being supplied by others. The BWRS and SCU are unique; there are no other similar systems anywhere. Knowing the harsh climate that the system will be operating in, the team is supporting other project partners to design and build a weather enclosure that will cover the entire system, protect it from weather, and provide climate-controlled comfort via its own HVAC system.

A bit of background

Whiteshell is a former nuclear research and development facility 4,375 hectares in size, located about 100 kilometres northeast of Winnipeg, MB. The reactor there played a key role in the nuclear history of Canada. Built in 1965, it served as a research reactor and became a testing site for the CANDU fleet before it was safely shut down in 1985. Since then, it has been kept in a state of “storage and surveillance.”

While the site is owned by the Canadian government, specifically Atomic Energy of Canada Limited (AECL), Whiteshell is operated by Canadian Nuclear Laboratories (CNL), a consortium which has the responsibility of safely decommissioning and remediating the site.

Eclipse is contracted by CNL for detail design for decommissioning and waste extraction, and waste recovery. At Whiteshell, legacy nuclear waste, over and above the reactor, includes contaminated lab coats, gloves, hand tools, and many other materials ranging from low-level to intermediate-level and high-level radioactive waste. The volume of legacy materials is currently being stored in seven bunkers and over 170 standpipes on the Whiteshell Site.

Revolutionary design and build

Eclipse was originally brought in to manufacture and assemble the retrieval systems and ended up taking on the design. The Eclipse team worked collaboratively with the customer to identify fixes that needed to happen, and to finish the job. The team delivered, and then some.

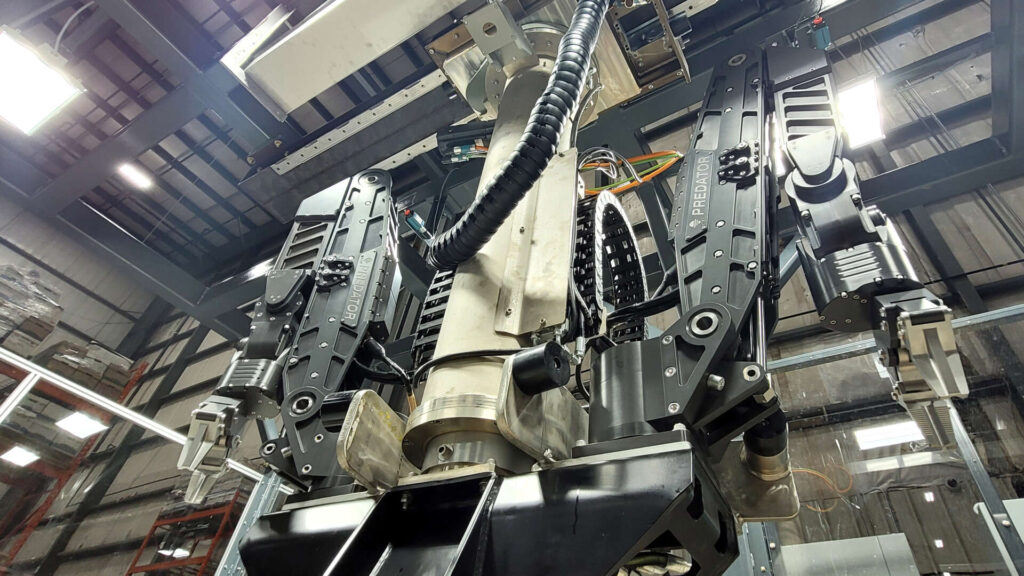

Eclipse engineers designed the system to be remotely operated, ensuring that no one will be in the area when waste is being removed. The system, built on a remote manipulator model, as opposed to a six-axis model, features an operator in a control room using hand controllers and watching on a CCTV camera system (Think Xbox on steroids.)

In choosing just the right manipulator, Eclipse went to market and developed a two-armed model based on manipulator arms that have been around for decades and proven reliable in adverse conditions, including extreme cold temperatures, which made it the right choice for northern Manitoba winters. The manipulator quickly became a member of the team, and they came to affectionately refer to it as Roma. With two arms suspended from an overhead gantry system, Roma can either pick up two things at once, or use both arms to pick up and move heavy or awkward items.

The operator, a construction tradesperson, will guide Roma to retrieve items coming from bunkers or standpipes and handle them inside the sorting and conditioning unit. From there, they will be placed into containers based on whether they are high-level, intermediate-level, or low-level waste. The containers are cylinders, which, essentially, are shielded waste storage and transport cans, with more shielding given to high-level items. These containers, when filled, will be transported to a storage facility in Chalk River, ON in the Upper Ottawa Valley for ongoing safe management.

What CNL was most impressed by was that the Eclipse team not only designed the system, they thought about the long game – how the system would get from Cambridge, Ontario, where it was designed and built to the Whiteshell site, some 2,500 kilometers away an hour north of Winnipeg. Eclipse delivered a solution complete with detailed plans on how the modular system would be loaded for transport, and the route it would travel, taking into consideration what roads and bridges it would travel along the way. On arrival at Whiteshell, when it is unloaded, it will be staged in the correct order for assembly.

Building a full-scale model for testing

Once the system was built, it was ready for Integrated Systems Operations Testing (ISOT). Eclipse approached CNL with an idea; let’s test the equipment in Cambridge, rather than onsite at Whiteshell. The advantage would be the proximity to the people who manufactured the equipment. CNL saw the benefit and agreed.

In their own backyard, Eclipse built a full-scale bespoke mock-up of the Whiteshell site, including 4 bunkers, 8 standpipes, a transformer station, remote control centre, and an operator and maintenance training facility. As of July 2023, equipment was being moved outside of the facility where it was built for testing. This will involve integrating systems from Eclipse and partner companies, as well as training construction tradespeople from the site execution partner, Bird Construction, whose people will operate the equipment. Eclipse will take on the contract for site execution, which will include providing technical experts for commissioning, operations support, and maintenance.

Challenges met

When Eclipse designers looked at the original design provided to them by CNL, they knew they had some serious work to do. They would have to adapt the plan and make the system modular, so that all pieces could be put on trucks and transported safely overland.

Another angle of the original concept that Eclipse engineers had to re-think was how to handle getting the system, which weighs in at over one million pounds, from one bunker to another. The original plan called for disassembling the entire structure at the bunker that had just been emptied, moving the pieces to the next bunker, and rebuilding it.

The Eclipse team had a better and much safer plan. They partnered with Mammoet, a company that specializes in picking up and moving big things, and together they mapped out a plan for moving the system from one bunker to another. The solution? Self-propelled modular transporters (SPMTs), which are platform heavy haulers with a large array of wheels, used for transporting massive objects, such as spacecraft, cranes, and other objects too big or heavy for trucks. Relying on these reduces technical, environmental, and safety risks and boosts efficiency.

What’s next

The Eclipse decommissioning system is getting noticed by others in the nuclear sector and beyond. People are impressed that it is a turnkey solution, and what’s more, is that Eclipse went beyond the detailed designing, building, and assembly to take on full system integration testing and training as well. The engineering that went into this project will be used in the future for other projects.

The Whiteshell decommissioning system was designed and built to nuclear industry quality standards by a highly-skilled team, with exceptional attention to detail. What the customer appreciates most is that Eclipse delivered on time and on budget, which is critically important in the nuclear world.

For more information about CNL Whiteshell, visit their website: Whiteshell Laboratories Decommissioning – Canadian Nuclear Laboratories (cnl.ca)

For more information on Eclipse Automation, go to www.eclipseautomation.com or email [email protected].