As smart manufacturing continues to evolve, businesses across industries are turning to advanced industrial automation to streamline operations, reduce costs, and stay competitive. But to truly unlock the potential of Industry 4.0, manufacturers must move beyond rigid, off-the-shelf automation solutions.

Standardized systems often lack the flexibility and precision required to keep pace with fast-changing markets and unique production requirements. In contrast, scalable and tailored automation systems—designed around specific workflows—offer significant advantages in performance, agility, and ROI.

Below, we explore the key benefits of shifting toward intelligent automation systems that fully leverage AI in industrial automation and align with the core principles of smart manufacturing.

In this article

- Standard automation limits growth – Generic systems lack the flexibility and precision needed to fully leverage Industry 4.0 and smart manufacturing.

- Purpose-built automation increases speed – Tailored solutions eliminate inefficiencies and bottlenecks, accelerating production cycles.

- AI-powered systems improve quality – AI in industrial automation enables real-time defect detection and higher product consistency.

- Smarter systems lower costs and boost ROI – Optimized resource use and better efficiency lead to greater long-term savings and sustainability.

- Future-ready automation gives you an edge – Scalable, intelligent systems enable easier upgrades, agility, and a unique competitive position in the market.

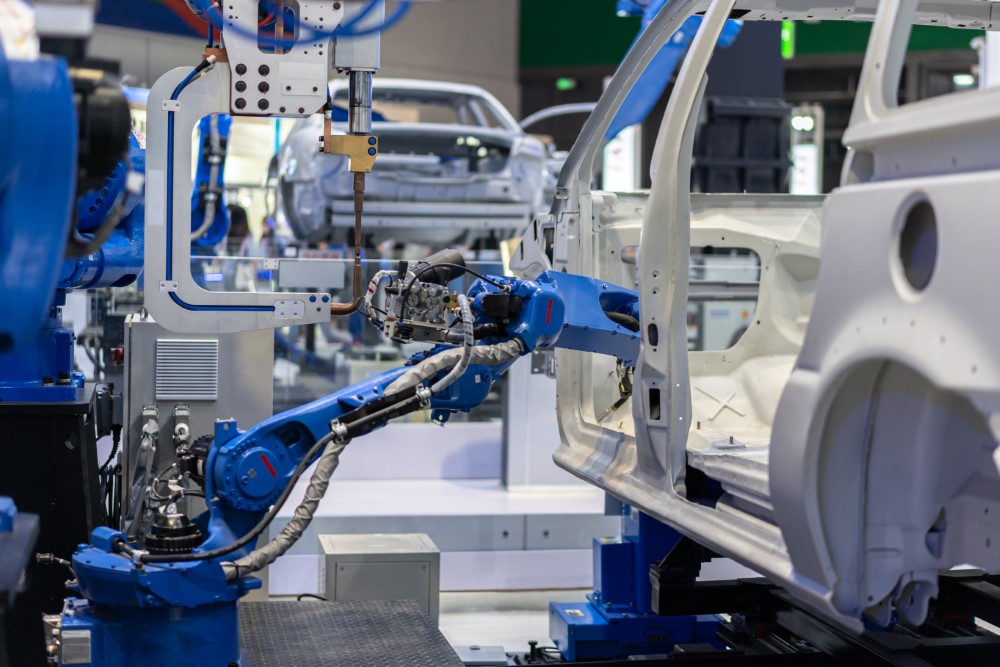

Faster production through purpose-built systems

Speed is a cornerstone of modern manufacturing. While standard automation can improve throughput, systems designed to match your specific production processes eliminate unnecessary steps and bottlenecks—leading to significantly faster cycle times.

Instead of adapting your workflow to generic machinery, intelligent automation enables your equipment to work seamlessly with your materials, components, and processes. This level of alignment translates to greater efficiency and more consistent production output.

Better quality control, fewer defects

In smart factories, quality assurance is no longer reactive—it’s proactive. Automation systems that are optimized for your specific product reduce variability and improve consistency. When paired with AI in industrial automation, these systems can detect defects in real time and adjust accordingly, ensuring higher product quality and lower scrap rates.

Tailored automation isn’t just about speed—it’s about precision, repeatability, and maintaining exact standards across every production run.

Lower operational costs and higher ROI

One of the driving forces behind the shift to industrial automation is cost reduction. But manufacturers often leave money on the table when they rely solely on general-purpose systems. By optimizing systems for resource usage, labor efficiency, and production time, businesses can unlock significantly greater cost savings.

Smart manufacturing systems also make better use of raw materials and energy, helping businesses reduce waste and meet sustainability goals—an increasingly important factor for investors and customers alike.

Easier future upgrades and greater flexibility

Manufacturing isn’t static—and your automation shouldn’t be either. Systems designed with scalability in mind allow for easier modifications and upgrades as product lines evolve. This future-readiness is especially critical in industries experiencing rapid innovation, such as electronics, medical devices, and electric vehicles.

By embracing Industry 4.0 technologies, such as cloud connectivity, real-time analytics, and predictive maintenance powered by AI, your systems can grow with your business, rather than hold it back.

In a crowded marketplace, differentiation is key. Implementing automation systems purpose-built for your business operations creates a unique production capability that competitors can’t easily replicate. It also positions your brand as a technology leader, ready to deliver consistent quality, faster turnaround times, and agile production at scale.

This strategic advantage enables you to take on more complex customer demands and open new revenue opportunities across verticals.

Why so many companies still settle for standard solutions

Despite the clear advantages, many manufacturers stick with generic systems—usually due to lack of awareness or concerns about upfront investment. While standardized solutions may appear more convenient at first, they often come with hidden long-term costs, including inefficiencies, limited scalability, and missed opportunities.

As AI in industrial automation becomes more accessible, the case for smarter, more adaptive systems grows stronger every year.

Partner with right vendor for scalable smart automation

At Eclipse, we help companies move beyond one-size-fits-all automation by delivering scalable industrial automation solutions tailored to their production needs. Whether you’re building complex assemblies or scaling up a high-volume product line, our experts integrate the latest Industry 4.0 technologies to create smarter, more connected manufacturing systems.

From industrial, to consumer goods, to life sciences, we’ve done it all. We’ve even helped the EV market by providing superior electric vehicle assembly automation solutions throughout the years. No matter what your business produces, Eclipse can help you get the most out of your customized automation machinery.

Book a no hassle pre-automation discussion with a factory automation expert.