Industrial automation plays a vital role in advancing innovation, efficiency, and safety across the healthcare and Life Sciences sectors. From pharmaceuticals and biotechnology to medical device manufacturing, automation is essential for meeting growing demand, maintaining compliance, and ensuring consistent product quality.

Manufacturers in the Life Sciences space are leveraging smart manufacturing, AI in industrial automation, and Industry 4.0 technologies to optimize operations and improve patient outcomes. Whether it’s automated assembly of medical devices, cleanroom production, or scalable systems for rapid growth, intelligent automation delivers measurable benefits.

This industry operates under strict regulatory requirements and demands high precision, traceability, and efficiency. Scalable and intelligent automation solutions help manufacturers meet these expectations while staying flexible and ready to adapt to evolving market and regulatory needs.

In this article

- One solution streamlines operations, boosts productivity, and reduces costs.

- Boost productivity by automating repetitive tasks, eliminating bottlenecks, and enabling 24/7 manufacturing operations.

- Improve quality control with precision systems and AI-powered inspections that reduce defects and waste.

- Cut operational costs through optimized workflows, reduced labor needs, and predictive maintenance.

- Enhance safety by reducing human exposure to dangerous or repetitive processes with automated machinery.

- Gain flexibility and insights via scalable systems and real-time data analytics that support fast adaptation and smarter decision-making.

Key benefits of industrial automation in life sciences and medical devices:

- Precision and quality control in medical device manufacturing

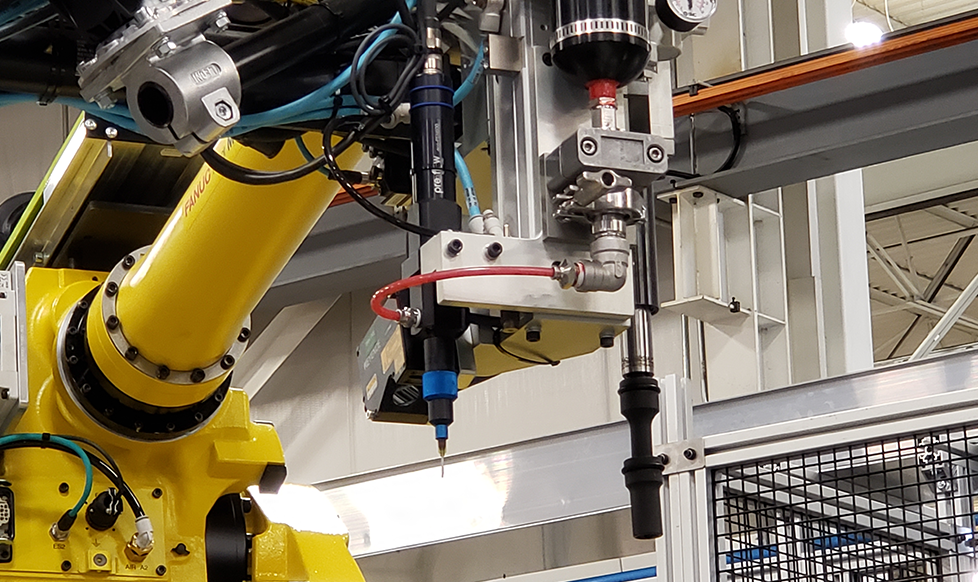

In medical device production, even small defects can have life-altering consequences. Eclipse’s medical device quality control automation solutions enable high-precision assembly, measurement, and inspection processes. Integrated vision systems and AI in industrial automation detect defects in real-time, ensuring every device meets compliance and patient safety standards.

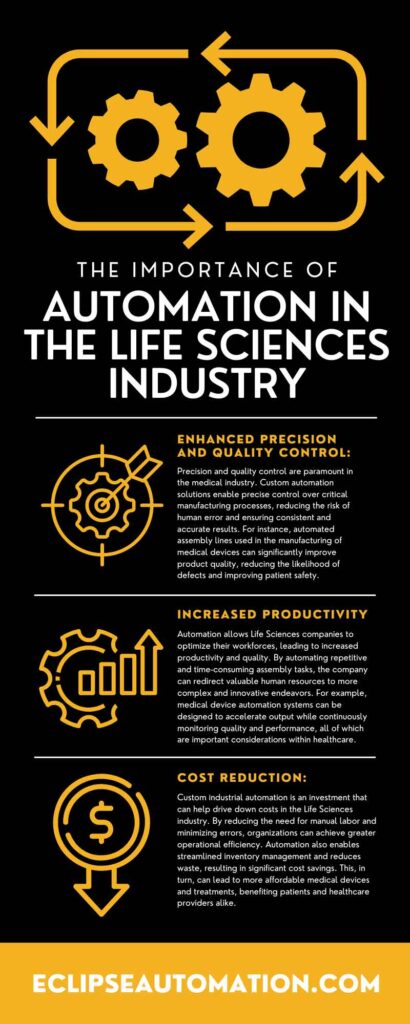

2. Higher throughput and productivity

Through automated medical device assembly, companies can accelerate throughput without sacrificing quality. Repetitive and labor-intensive tasks—such as device insertion, sealing, and packaging—are handled by high-speed systems, allowing human resources to focus on R&D and product innovation. High-speed medical device packaging is one area where automation has shown significant ROI.

3. Lower operational costs and waste reduction

Automation reduces labor costs, improves material usage, and streamlines inventory management—key benefits in medical equipment manufacturing automation. It minimizes human error and downtime, reduces product recalls, and supports sustainability goals, all while enhancing the bottom line.

4. Regulatory compliance and full traceability

Meeting international regulations such as FDA and ISO 13485 is critical in medical device manufacturing. Our systems offer comprehensive traceability, data logging, and digital documentation to support regulatory audits and ensure full compliance. These features are vital for cleanroom automation for medical devices and environments requiring sterile manufacturing conditions.

5. Faster speed to market for medical innovation

In the race to deliver the next breakthrough in healthcare, time matters. Smart manufacturing solutions from Eclipse Automation reduce lead times and support flexible production, helping you scale new treatments, diagnostic tools, and wearable health technologies faster than competitors. This speed to market not only boosts revenue potential but also enhances your reputation as an innovation leader. Enhanced precision and quality control: Precision and quality control are paramount in the medical industry. Custom automation solutions enable precise control over critical manufacturing processes, reducing the risk of human error and ensuring consistent and accurate results. For instance, automated assembly lines used in the manufacturing of medical devices can significantly improve product quality, reducing the likelihood of defects and improving patient safety.

Real-world applications of automation in life sciences

- Pharmaceutical manufacturing – Automation streamlines everything from tablet pressing to packaging and labeling, improving consistency and reducing contamination. This makes it easier to scale while ensuring safety and dosage accuracy.

- Medical device automation – Automation enhances the precision medical device production required for critical instruments like insulin pens, diagnostic test kits, and surgical tools. Standardized assembly techniques, robotic inspection systems, and predictive maintenance ensure every unit meets exact specifications.

- Health food and supplement automation – As consumer demand rises, health food manufacturers are turning to automation to ensure accurate formulation, temperature control, and packaging. Our systems are easily adaptable to new ingredients and packaging formats, supporting evolving market demands.

What this means for the life sciences Industry

What this means for the life sciences industry

The advantages of automation in Life Sciences—particularly in medical device automation—are undeniable. Enhanced precision, increased throughput, reduced costs, and faster delivery all play a critical role in transforming global healthcare.

With digital transformation in medical device production accelerating, now is the time to invest in smart, scalable systems. At Eclipse Automation, we help your organization unlock new levels of performance through industrial automation that’s intelligent, compliant, and future-ready.

Incorporating custom automation of medical industry devices puts the industry in a prime position to unlock new frontiers in precision medicine, personalized healthcare, and improved patient outcomes. By harnessing the power of quality industrial automation in their manufacturing plans, Life Sciences organizations can shape a brighter future where technology and human expertise work in perfect synergy to advance the boundaries of medical science and make a meaningful impact on global health.

Book a no hassle pre-automation discussion with a life sciences factory automation expert.