Each year, advancements in automation technology push the boundaries of what’s possible — especially in the field of medical device manufacturing. Once considered a cutting-edge approach, automation is now an essential part of staying competitive in this highly regulated, high-precision industry.

If your business is still relying on manual production methods, it may be time to consider how industrial automation can transform your operations. From enhanced precision to 24/7 operations, automation is revolutionizing how medical devices are produced, packaged, and delivered.

In this article

- Industrial automation delivers unmatched accuracy and repeatability in medical device production, ensuring quality and reducing human error.

- Automated systems accelerate production, helping medical device manufacturers meet surging demand and respond quickly to market shifts.

- While automation requires upfront investment, it significantly reduces labor costs, increases uptime, and improves resource utilization over time.

- Smart factory automation integrates real-time quality checks, traceability, and documentation to meet strict medical device regulations.

- Automation reduces worker exposure to repetitive, delicate, or hazardous tasks, enhancing safety in medical device manufacturing environments.

- Automated systems adapt quickly to new products or changes, giving manufacturers the agility to innovate and lead in a dynamic market.

Precision and consistency: The backbone of medical device manufacturing

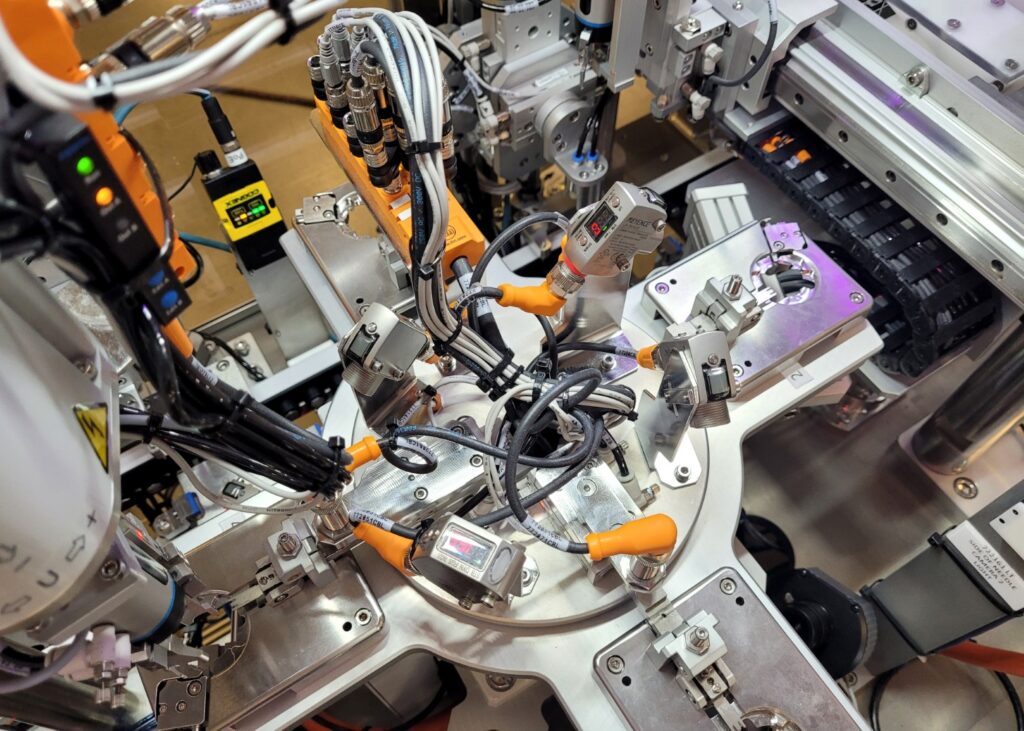

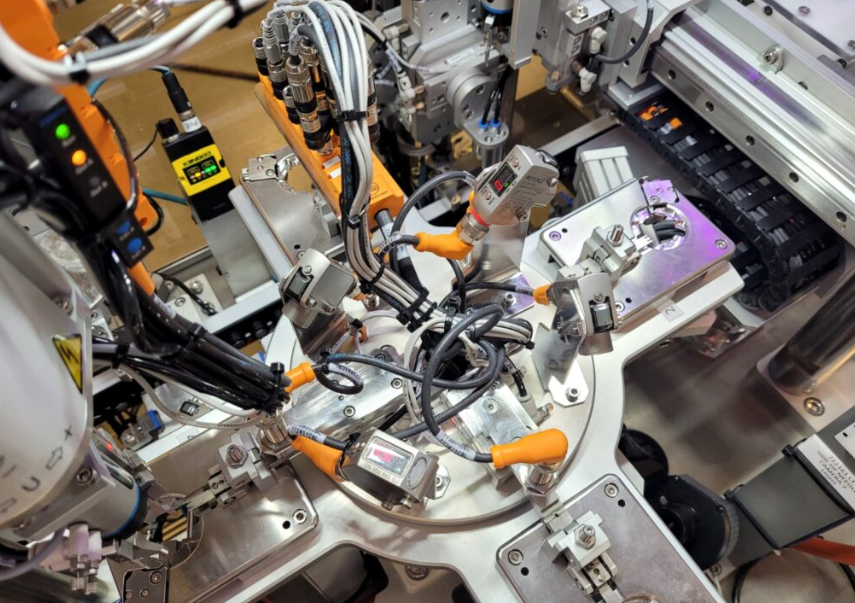

In medical device production, precision is not optional — it’s life-critical. Industrial automation ensures exceptional accuracy in even the most intricate manufacturing processes. Robots and smart systems can assemble components with sub-millimeter precision, ensuring every device meets exacting quality standards.

Consistency is equally vital. With automation, you eliminate variability in production, significantly reducing the risk of human error. This is especially important in smart factory environments, where data-driven systems ensure continuous quality at scale.

Faster time to market:

One of the biggest advantages of automation in medical device manufacturing is speed. Automated lines can produce goods at a rate far exceeding manual processes. Whether it’s high-volume production or rapid prototyping, industrial automation allows manufacturers to respond quickly to market demand.

This ability is crucial in times of crisis — such as during a pandemic — when the need for medical devices can surge overnight..

Lower cost, greater efficiency:

While implementing automation in medical device production may involve upfront costs, the long-term savings are substantial. Machines operate around the clock, reduce waste, and require fewer human interventions, which leads to lower labor costs and minimized downtime.

Through smarter resource allocation and process optimization, manufacturers can increase their ROI and lower the cost per unit — making medical devices more accessible to the global healthcare market.

Built-in quality control and regulatory compliance:

Strict compliance with regulatory bodies like the FDA, ISO, or CE is a non-negotiable in medical device manufacturing. Automated systems incorporate sensors, vision systems, and AI to inspect, monitor, and track every unit in real time.

In a smart factory, every step of the process is logged and verified, supporting robust documentation and audit readiness. This improves traceability, enhances quality assurance, and drastically reduces the risk of recalls.

Flexibility and adaptability:

The medical device industry is dynamic. New products, changing regulations, and evolving healthcare needs demand flexibility on the production line. With industrial automation, manufacturers can reconfigure systems quickly to accommodate new product types or updates to existing designs.

This agility enables medical device manufacturers to scale production and pivot without major delays or disruptions — a key advantage in a competitive landscape.

Safer working environments:

Automation also significantly improves safety on the shop floor. In many medical device manufacturing processes, workers are exposed to repetitive tasks, delicate components, or even hazardous substances. Automated systems reduce these risks by taking over high-exposure or high-strain tasks.

Robotic arms, for example, can handle micro-assembly tasks or hazardous material disposal — improving overall employee well-being while maintaining operational continuity.

End-to-end traceability and documentation:

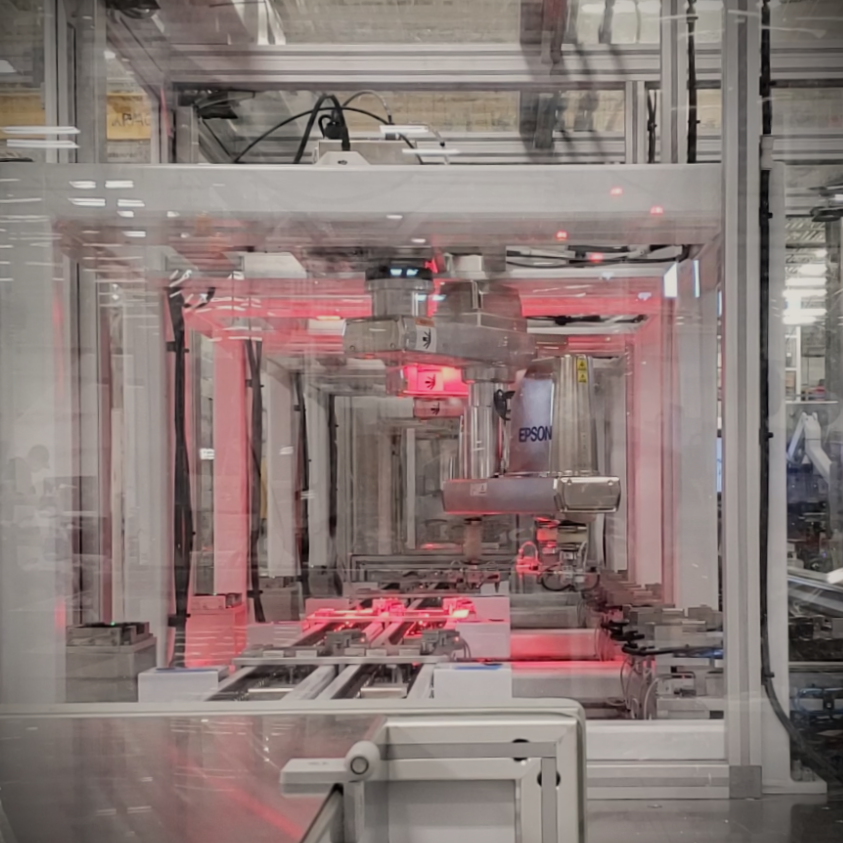

Every product in the medical device industry must be traceable — from raw material sourcing to final packaging. With smart factory systems in place, automated platforms capture every detail along the production journey, storing it in centralized databases.

This not only aids in regulatory compliance and audits but also supports post-market surveillance and quality assurance across the entire lifecycle of a medical device.

Enabling innovation and customization:

By automating repetitive and time-consuming tasks, manufacturers can redirect skilled talent toward innovation, design, and process improvements. This shift supports the creation of more advanced, customized medical devices that better serve patient needs.

Automation doesn’t replace people — it empowers them to focus on higher-value work that drives growth and innovation in the medical device sector.

24/7 operations and global supply chain readiness:

Industrial automation enables medical device manufacturers to run production lines 24/7. This continuous operation is a game-changer for companies that serve international markets, where demand cycles differ by region.

In a globalized industry, maintaining a constant supply of high-quality medical devices is essential. Automation ensures production never stops — even as demand fluctuates.

Gaining a competitive edge:

Adopting automation is no longer a luxury — it’s a strategic necessity. Companies that leverage smart factory technologies and automated systems are faster, more agile, and more resilient. They can adapt to market changes, meet regulatory requirements, and deliver superior medical devices with greater consistency.

By embracing industrial automation, medical device manufacturers position themselves as forward-thinking leaders in a rapidly evolving landscape.

The advantages of industrial automation in medical device production are numerous, revolutionizing the way manufacturers approach innovation, precision, and efficiency. As the industry continues to evolve, automation will continue to play a pivotal role in shaping the future of medical device manufacturing, ensuring the delivery of cutting-edge, high-quality products to meet the ever-growing demands of the health care sector. The future of medical device production lies in smart, automated, and data-driven systems. Whether your goal is to improve quality, reduce costs, or increase capacity, industrial automation offers the tools to get there.

As more companies invest in smart factory solutions, the entire medical device manufacturing industry is being reshaped — becoming faster, safer, and more innovative. If your organization is ready to stay ahead of the curve, automation isn’t just an option. It’s the way forward.

Book a no hassle pre-automation discussion with a medical device expert.