Automating battery dismantling and discharging for sustainable lifecycle management.

Welcome to our Transportation and Battery Recycling Capabilities Page

We are thrilled to share with you our experience in designing and building

revolutionary automated systems for dismantling and discharging batteries for recycling.

The short video below details our extensive work within the Transportation industry. We look forward to future discussions on how we can help you elevate your business with our innovative automated solutions.

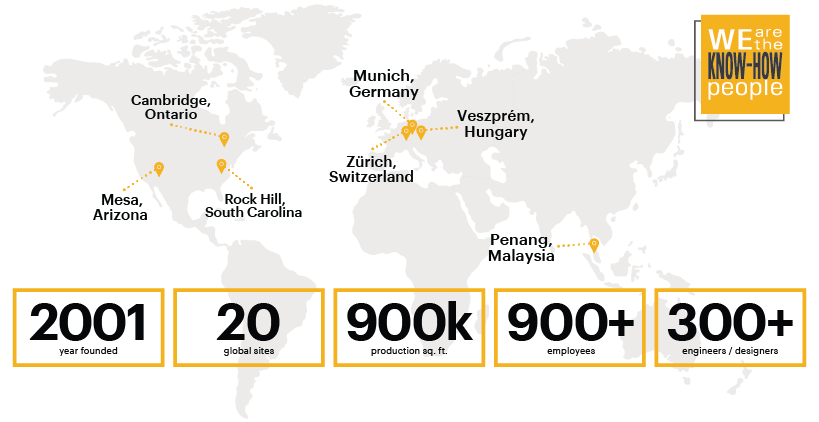

A Global Network of Expertise

Importance of battery recycling – The Eclipse Advantage

When it comes to EV batteries, Eclipse Automation closes the loop, from automated battery production through to automated recycling solutions, always adhering to sustainability, safety, and traceability requirements.

Challenges in battery recycling

- Avoid wasting resources

- EU legislation on sustainability, safety, traceability and the recycling of batteries

- Handling high variability and continuously expanding product types

- Scalable solution for future growth of the industry

- Traceability and performance improvement by data processing solutions

- Continuous improvement on sustainable production, dismantling & discharging, reuse of raw materials

With our automated dismantling and discharging capabilities, customers can reach more than 95% recovery rate of raw materials.

Our goal in the Transportation and Battery Recycling industries:

To lead the way in automotive and battery recycling through designing and building innovative automated systems that enable our customers to rebuild old battery systems, on-time, and on-budget and the re-use of valuable raw materials.

Eclipse Automation, part of Accenture, is YOUR STRATEGIC PARTNER

Leading-edge manufacturing & advanced automation solutions

We understand the challenges and have the solutions to boost cost-efficiency and productivity for your business.

Agile European sites with a global network via Eclipse and Accenture

We have the Eclipse know-how and resources in advanced manufacturing automation, combined with Accenture’s deep digital transformation expertise.

Proven EV assembly experience

We deliver future-forward automation solutions that enable our customers to align with sustainable economic goals.

Why Partner with Eclipse?

- We are able to design, plan and build a sustainable, innovative, automated facility; quickly and cost-effectively.

- We know how to assess and utilize the full potential of the latest technologies.

- We know the industry and its challenges and trends.

- We have a large, global ecosystem of expertise.

Our Solution

Unit

- Dismantling and discharging line

Cycle Time

- Designed to meet customer requirements

Technologies

- Automatic / manual unboxing / unloading

- Automatic / manual pack opening

- Discharging

- Automatic / manual dismantling

- Automatic / manual module removal

- AI recognition of types and process initiation

We know that every business needs a different solution, and our expertise lies in providing custom offerings tailored to our customer’s specific business preference.

Hardwired WPC based transfer system

Flexible AMR based transfer systems

Eclipse Services

- Training Simulation and Service

- Digital Twin and Mixed Reality Simulation

- Process Storyboarding

- 3D Modelling and Robot Simulation

- Plant Layout

- Concept Engineering

- 24 / 7 Support

- Optimization OEE

- Inspection and Maintenance

- Copper Laser Welding

- Digital Twin

Strength in Collaboration

Eclipse Automation is proud to be a part of Accenture – combining a powerful set of skills and technologies for our clients.

Artificial Intelligence: AI can hone system performance with applications for condition monitoring and predictive maintenance

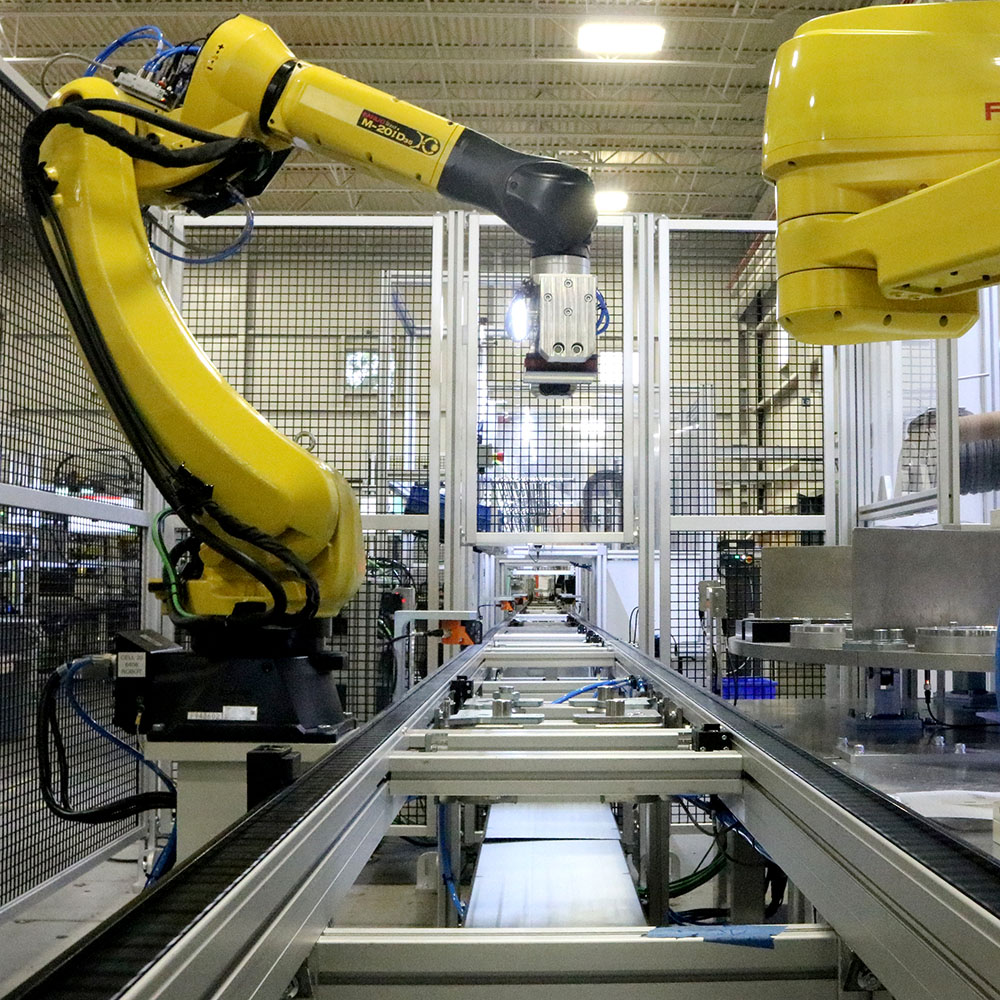

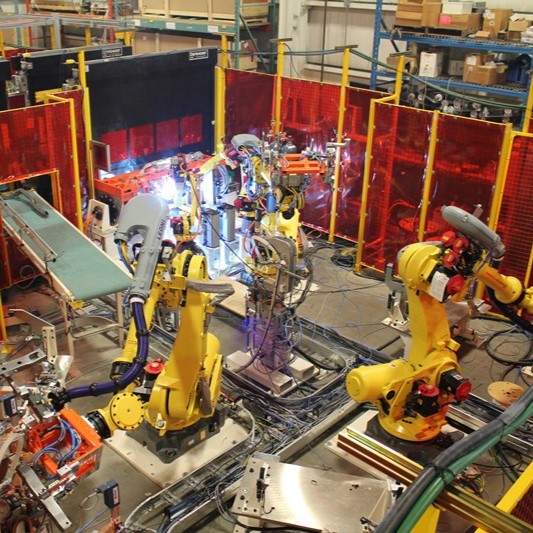

Industrial Robotics: The use of robots, computer-controlled robotic devices designed to assist a person, can mitigate risk and accelerate performance

Digital Twins: Simulations and digital threads can support more efficient design and interactive training efforts

Special Tools: Automated Flaw / Non-Destructive Examination (NDE) Analysis and Custom Document Management tools can apply the latest digital resources to a system

Sustainability: Industry 4.0 adoption has encouraged internal and external sustainability practices to be integral to the plan

Contact our Experts

Eclipse Automation Germany GmbH

Feldlerchenstraße 12-14, 85467 Neuching

Tel: +49 (0)8123 9871-0

Email: [email protected]