Production challenges that automation solves

On today’s competitive manufacturing landscape, industrial automation has emerged as a transformative solution to address various production challenges. As a guide, we’ve put together a list of main production challenges that automation can solve. By integrating advanced technologies and streamlining processes, automation offers a range of benefits that can revolutionize your manufacturing efforts. This article explores some common production challenges faced by manufacturers and highlights how industrial automation can effectively overcome them and improve business operations.

1. Increased productivity:

One of the primary goals for manufacturers is to enhance productivity and output, and this can be difficult given the continued labour shortage in many markets. Industrial automation can reduce manual labour, eliminating bottlenecks, and optimizing workflows. Automated systems can operate around the clock with minimal downtime, resulting in increased production efficiency and higher throughput rates. Product changes can also be reprogrammed and adjusted without upskilling and retraining staff, making operational pivots easier.

2. Quality assurance:

Maintaining consistent product quality is crucial for customer satisfaction and brand reputation. Industrial automation employs precision-controlled processes, reducing human error and ensuring consistent quality standards. Automated inspections and testing equipment can detect defects or deviations more accurately, leading to improved product quality and reduced waste.

3. Cost reduction:

Controlling production costs is a constant challenge for manufacturers. Industrial automation helps mitigate this by optimizing resource allocation, reducing labour expenses, and minimizing material waste. Automation streamlines operations, enhances energy efficiency, and enables predictive maintenance, all contributing to significant cost savings over time.

4. Workplace safety:

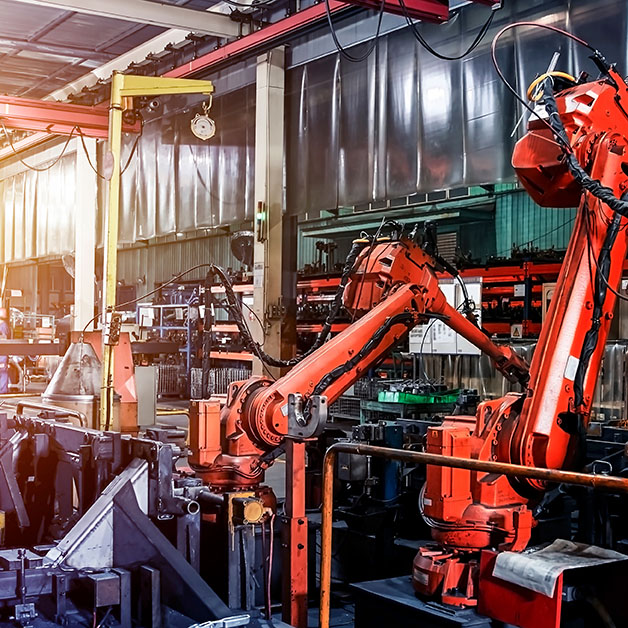

Ensuring a safe working environment is of paramount importance. Industrial automation reduces the risk of accidents by minimizing human involvement in hazardous tasks. Robots and automated systems can handle physically demanding or dangerous operations, protecting workers from potential injuries. Safety protocols and monitoring systems are integrated into automation solutions to maintain a secure production environment.

5. Scalability and flexibility:

As market demands change, manufacturers must adapt quickly. Industrial automation offers scalability and flexibility to accommodate varying production requirements. Automated systems can be easily reconfigured or reprogrammed to handle new products or process changes, allowing manufacturers to respond swiftly to market shifts and maintain a competitive edge.

6. Data analytics and insights:

Industrial automation generates vast amounts of data that can be leveraged for continuous improvement. By analyzing real-time production data, manufacturers gain valuable insights into performance metrics, operational bottlenecks, and areas for optimization. Data-driven decision making enables proactive maintenance, predictive forecasting, and process refinement, leading to enhanced efficiency and competitiveness.

Eclipse Automation’s expertise in industrial automation presents a powerful solution to overcome production challenges faced by manufacturers. From boosting productivity and ensuring quality to reducing costs and enhancing workplace safety, automation streamlines operations and drives efficiency gains. Embracing industrial automation empowers manufacturers to meet evolving market demands, maintain a competitive edge, and achieve sustainable growth on today’s dynamic manufacturing landscape. By harnessing the transformative capabilities of automation, manufacturers can unlock new opportunities and propel their businesses forward.