Tracey Thomas, Content Communications Specialist

In today’s fast-paced manufacturing and distribution environments, businesses face constant pressure to move products faster, reduce errors, and do more with less… less space, less labour, and fewer resources. The less is more rhetoric is more common today than ever. Traditional, manual material handling processes were once the norm; now, they slow operations down due to inefficiencies, worker injuries, and errors, all of which can add up to real losses in both time and money.

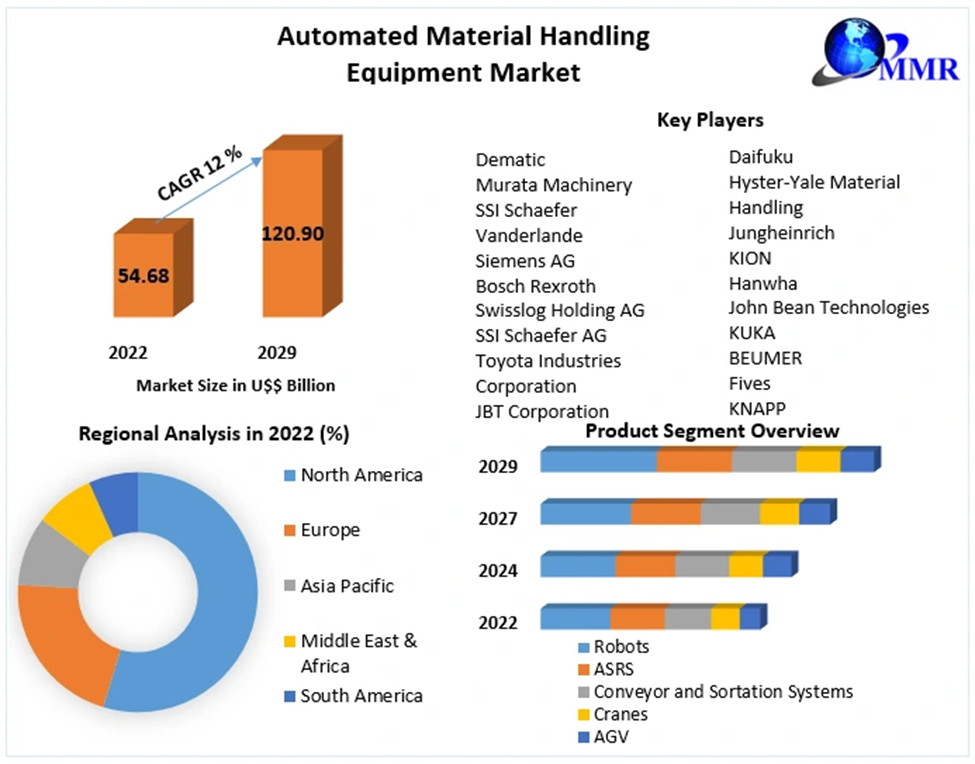

According to research, there is significant opportunity to improve the bottom line by improving material handling operations. In fact, 52% of material handling companies plan to increase their investment in robotics over the next two years with an expectation that technology, including AI will significantly impact inventory management and material handling in the next 5 years. With such opportunity to improve material handling in the future, this can be point of differentiation and competitive advantage, especially in ultra-competitive markets.

In this article

- AMHS reshape modern manufacturing by addressing inefficiencies, reducing errors, and optimizing resources.

- Global market growth trends show AMHS reaching $141.86 billion USD by 2030, with Canada leading North America’s growth.

- Physical systems like conveyor belts and robotic arms integrate with AI, IoT, and Industry 4.0 technologies.

- Key benefits include increased efficiency, enhanced accuracy, improved workplace safety, and long-term cost savings.

- Amazon’s AMHS implementation improves fulfillment speed, reduces packaging waste, and supports employee upskilling.

- Eclipse Automation integrates AMHS into custom solutions to optimize workflows and enhance operational flexibility.

Systems of the future: What are Automated Material Handling Systems?

It’s no surprise that businesses turn to Automated Material Handling Systems (AMHS): smart, integrated technologies that help companies streamline workflows. These systems, when properly integrated, can reduce labour costs up to 75% depending on facility size, staff, and scope! From improving safety and speed, to long-term savings and scalability, AMHS are quickly becoming essential for companies looking to stay competitive.

As businesses face constant pressure to move products faster, reduce errors, and optimize resources, the global demand for AMHS is growing rapidly. This demand is reflected in the market, which is predicted to reach $79.07 billion USD in 2025 and $141.86 billion USD by 2030. North America leads the charge, with Canada recognized as the fastest-growing market, forecasted to grow at approximately 19% from 2024 to 2029.

Combining physical and digital tenets

Imagine a factory floor where a robotic arm assembles a product with flawless precision, while an autonomous guided vehicle (AGV) swiftly retrieves the next component from storage, ensuring seamless production without a moment of delay. AMHS is making this future a reality.

AMHS integrate machines and digital tools to automate material movement, storage, and retrieval with minimal human input. From conveyor belts to robotic arms, these systems are transforming industries like manufacturing, automotive, consumer/industrial automation, and even energy industries, by improving speed, safety, and accuracy.

But AMHS go beyond the physical. The integration of robotics, artificial intelligence (AI), Internet of Things (IoT), and Industry 4.0 technologies is transforming their efficiency and scalability. For example, manufacturers are using advanced tools like smart city systems and digital twins — virtual models of physical processes — to optimize operations and IoT sensors in AMHS can monitor equipment performance in real-time, enabling predictive maintenance and reducing downtime. Similarly, industries like e-commerce rely on AMHS to efficiently manage high volumes of goods. These advancements are powered by technology, enabling smarter and more efficient operations.

Looking to the future: Implementing AMHS

AMHS positions companies ahead in a globally connected world, serving as the backbone of efficient, scalable, and safe modern manufacturing. Key benefits include:

- Increased efficiency and productivity: Operating 24/7 with minimal downtime, AMHS significantly reduces material movement time between processes or storage locations. For example, Amazon has leveraged AMHS to achieve 75% faster fulfillment in identifying items and storing inventory across its operations network. By automating repetitive tasks, AMHS also frees up employees to focus on higher-value activities, making roles more appealing to prospective talent.

- Enhanced accuracy and reduced errors: By minimizing human error, AMHS ensures correct material handling sequences, especially when integrated with warehouse management systems (WMS). Amazon’s systems have also reduced per-shipment packaging weight by 41%, showcasing how automation can optimize processes while reducing waste.

- Improved workplace safety: Beyond e-commerce, industries like automotive and aerospace (and more!) leverage AMHS to streamline production cycles and improve safety, as AMHS reduces accidents by taking over tasks like heavy lifting, forklift operations, and navigating cluttered spaces. By addressing ergonomic concerns and compliance with lifting regulations, AMHS creates safer environments for workers while positioning companies as attractive employers who prioritize employee well-being.

Additional benefits include space optimization through high-density storage solutions and scalability via modular designs. Integration with analytics tools enables better decision-making on inventory, workforce allocation, and process improvements by management.

While upfront costs for hardware, integration, and infrastructure upgrades are significant – averaging between 8 to 22 months ROI depending on the industry –, AMHS offers long-term savings through improved efficiency, reduced downtime, lower energy consumption, and optimized equipment usage. Ensuring optimized equipment usage means anticipating technical issues; this requires skilled intervention, emphasizing the need for careful planning and alignment with existing systems like ERP, MES, or WMS.

Other challenges include addressing employee concerns about job displacement, which can be mitigated through upskilling and new roles alongside AMHS. Furthermore, a lack of available labor challenges many warehouse operations, but this can be addressed by optimizing labour allocation through AMHS. These systems enable workers to focus on higher-value decisions and services, while eliminating the need for employees to perform low value, repetitive and high-risk tasks like heavy lifting, which in turn improves job satisfaction, safety and efficiency.

How Eclipse is reshaping modern manufacturing

Overall, AMHS has the potential to revolutionise how warehouses operate. Although the full use case and technologies are still developing – meaning that the role of AMHS may change in the future – there is still significant potential for companies to gain competitive advantage by creating a AMHS strategy and implementing technologies to help achieve their goals to optimize workflows, maximize space utilization, and enhance operational flexibility to achieve faster production cycles, reduce errors, and adapt to evolving demands with scalable, modular solutions.

Discover how Eclipse Automation can transform your operations with tailored automation strategies that reduce risk, boost efficiency, and drive performance in today’s competitive market. Book a Discovery Call today!

Get in touch to explore how our Advanced Engineering Services can help you move faster without compromising results.