Mac MacSorley, Service Manager, North America, Eclipse Automation

Why customer lifecycle management can make or break your project

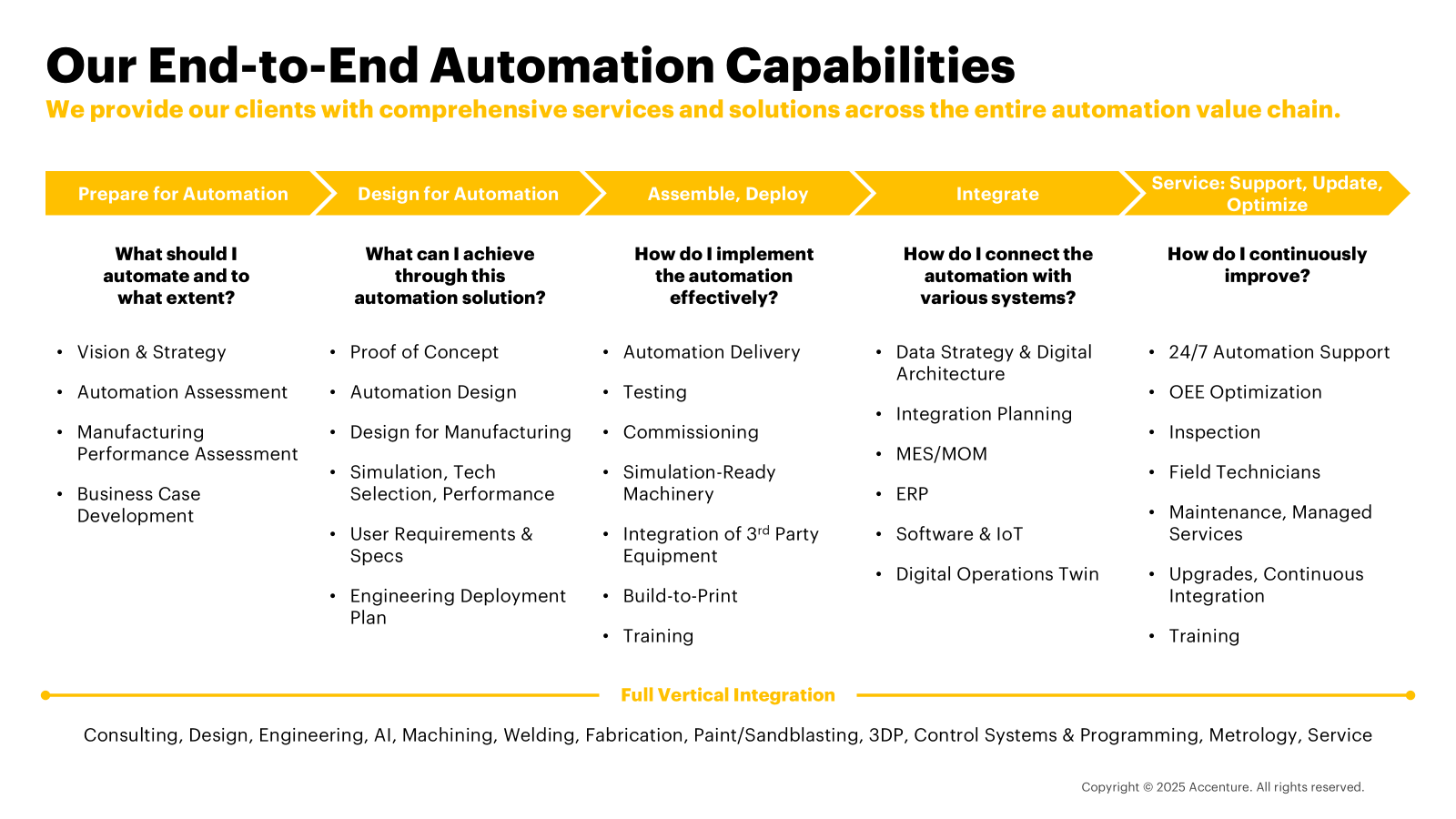

The complexity of modern automation projects can be overwhelming: employee training, skills gaps, technology integration, strategic planning, and countless other variables. Miss one critical element, and your multi-million-dollar investment could become another statistic. But with the right service mix, any problem can be mitigated.

In our experience, it’s Customer Lifecycle Management (CLM) that makes the difference between automation projects that achieve their objectives while meeting cost and timeline goals and those that fail.

And it’s not just us: research across the manufacturing industry has shown that organizations with comprehensive CLM are more likely to reach project completion within budget and schedule, with 61% hitting or exceeding their cost reduction expectations. When you consider that just 2.5% of companies without systematic lifecycle management are able to complete all their projects successfully, the advantage is clear.

In this article

- Customer Lifecycle Management reduces costs and increases success rates by providing expertise across pre-automation planning, implementation, and post-automation optimization.

- Eclipse’s comprehensive tracking system monitors all project stages—from design through post-implementation—giving clients real-time visibility and control.

- Often-overlooked elements like spare parts strategy and obsolescence planning can make the difference between success and costly failure.

- A practical checklist helps identify critical lifecycle management considerations before problems arise.

Pre-automation: Setting a foundation for success

The foundation of any successful automation project is laid long before the first robot arrives on the factory floor. Research shows that when organizations invest in comprehensive pre-automation services, they can achieve up to 40% faster commissioning—while significantly reducing implementation risks.

This is why Eclipse has invested so heavily in Advanced Engineering Services (AES), a uniquely comprehensive pre-automation suite that includes process assessments, data-driven decision support, digital twin development, and virtual commissioning, as well as strategies for reducing cost and risk, and planning for change and training. AES allows clients to essentially test-drive their entire production line in a virtual environment before spending a single dollar on hardware. It’s an approach we’ve developed over many years, to help us identify potential bottlenecks, optimize layouts, and validate system designs—catching expensive mistakes when they’re still just pixels on a screen.

AES isn’t only about technology validation. It’s also about filling knowledge gaps with independent expertise, providing fresh perspectives and the required technical skills to solve long-standing challenges, and ensure your team has the skills needed for success. Nearly half of all manufacturers report facing significant challenges finding skilled workers to fill critical positions, and the shortage is only getting more severe. Spotting these issues in advance gives them the lead-time to staff up effectively, or to redesign their processes to minimize hard-to-fill roles.

Implementation: Turning vision into reality

Without proper support, even the best-laid plans can falter during implementation. Being able to track all parts of a project—from design and engineering through manufacturing, coordination and implementation—often makes the difference between a successful end result and an endless cycle of delays and cost overruns. This is why Eclipse is one of the few automation providers to have developed a comprehensive monitoring system, that lets us provide real-time visibility for clients into exactly where their project stands at any moment.

This transparency lets organizations track the pulse of the project and plan for upcoming stages. The result is fewer surprises, less scrambling to coordinate between multiple vendors, and less time spent wondering if the project is truly on track.

Implementation support goes beyond project management. It includes change management for your workforce, integration of new systems and processes with existing infrastructure, and providing training and knowledge transfer that empowers your team for long-term success. The research backs this up: Organizations with strong implementation support report 35% reduction in machine downtime and 20% increases in throughput.

Post-automation: The journey doesn’t end at go-live

The last critical mistake many projects make is in perceiving the go-live point as a finish line, rather than a starting point. Post-automation services—including system deployment optimization, predictive maintenance, and continuous improvement—are where the real value emerges.

Consider spare parts strategy, an often-underestimated element of lifecycle management. Ordering critical spares during initial manufacturing can be especially cost-effective, potentially eliminating weeks of downtime waiting for custom components. Similarly, obsolescence planning helps organizations transition smoothly when equipment reaches end-of-life, rather than facing emergency replacements.

Industry implementations of comprehensive post-automation services have achieved 15% increases in overall plant effectiveness and 30% reductions in unplanned maintenance. Eclipse’s post-automation services are designed to deliver similar sustained competitive advantages that compound over time.

Your lifecycle management checklist

Time spent upfront significantly increases your chances of success and decreases project risk later on. Consider everything from process assessments, data, design, risk and change management. Here is a short checklist to help you identify key elements that need to be assessed when commencing an automation project. Before you embark on your next project, consider these critical lifecycle elements:

Pre-automation

- Feasibility study, process assessment, data availability and ROI analysis

- Digital twin/virtual commissioning

- Skills gap assessment, change management and training plan

- System design and integration requirements with existing systems

Implementation

- Real-time project tracking system

- Change management strategy

- Training and knowledge transfer protocols

- Contingency plans for common risks

Post-automation

- Continuous improvement metrics

- Spare parts strategy (order during manufacturing!)

- Predictive maintenance program

- Obsolescence planning timeline

The bottom line: Expertise when you need it most

Customer Lifecycle Management isn’t about adding complexity—it’s about having the right expertise available exactly when you need it. Whether it’s an independent perspective during planning, specialized skills during implementation, or optimization expertise post-launch, comprehensive lifecycle services fill the gaps that sink automation projects.

Ready to transform your automation project outcomes? Download our Advanced Engineering Services brochure or our Automation Readiness Checklist today! Contact Eclipse to learn how our comprehensive lifecycle management services—from pre-automation planning through post-implementation optimization—deliver the expertise and visibility you need for success.

Get in touch to explore how our Advanced Engineering Services can help you move faster without compromising results.