INNOVATIVE

NUCLEAR-ENGINEERED AUTOMATION SOLUTIONS

Powering safety, efficiency, and innovation in nuclear energy

Eclipse Automation is driving innovation in the energy industry through advanced industrial automation solutions that enhance safety, efficiency, and sustainability in nuclear and green energy.

We’re upgrading how the world powers itself, applying proven automation expertise from high-tech sectors to meet the unique challenges of nuclear energy.

Our nuclear expertise

Eclipse’s Nuclear Division is fully dedicated to the unique requirements of the nuclear energy sector. With decades of experience in reactor refurbishment, life extension, decommissioning, and advanced materials research, our team delivers smart automation solutions that make nuclear energy safer, more efficient, and more sustainable.

Industry challenges we solve

| Challenge | Our approach |

|---|---|

| Safety | Reduce human intervention in hazardous environments through robotic and remotely operated systems. |

| Efficiency | Streamline operations, minimize downtime, and optimize energy output through digital automation. |

| Sustainability | Support low-carbon energy through advanced solutions for nuclear, solar, wind, and hydrogen applications. |

| Scalability | Deliver tailored systems for nuclear facilities of all sizes, from SMRs to large-scale reactors. |

Nuclear energy solutions

Pioneering the future of nuclear automation

We design and deliver advanced automation solutions that address the most critical aspects of nuclear operations, from new build’s to decommissioning.

Our capabilities include:

- Precise control: Deliver automation technologies for reactor management, fuel optimization, and waste handling.

- Reduced human intervention: Deploy remote tooling and robotics that improve safety and performance.

- Energy optimization: Maximize fuel efficiency and minimize waste.

- Lifecycle support: Automate refurbishment, life extension, and decommissioning processes.

- Integrated systems: Develop multi-purpose nuclear waste retrieval, sorting, and packaging solutions.

- Reactor programs: Lead inspection, maintenance, and life-extension tooling for CANDU and international reactors.

- Hot cell design: Design and manufacture advanced hot cell systems for materials research.

- Next-generation builds: Support small modular reactors (SMRs) and large new-reactor projects globally.

- Training solutions: Conduct full-scale mock-up testing, commissioning, and operator training.

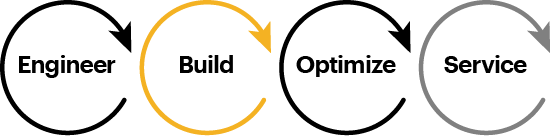

The nuclear energy lifecycle

From nuclear new-build strategies to refurbishment and life extension, Eclipse supports every stage of the nuclear energy lifecycle. Our fully integrated approach ensures end-to-end delivery of safe, efficient, and sustainable automation systems.

- Advanced engineering: Analyze nuclear workflows, define safety and efficiency KPIs, and develop tailored solutions.

- Automation: Engineer custom systems including advanced robotics, controls, and monitoring solutions for reliable, compliant operation.

- Post-automation: Validate real-world performance and fine-tune systems for long-term safety and efficiency.

- Vertical integration: Integrate shopfloor systems with enterprise platforms for real-time insights, predictive maintenance, and scalability.

Some of our recent projects

CANDU refurbishments

Design, development, and supply of custom tooling for CANDU6, Bruce Power, and OPG reactor refurbishments

Vertical flux detector removal

Design, supply, and execution support of flux detector removal and volume reduction equipment, enabling medical isotope production in CANDU reactors at Bruce Power

CanAtom/OPG installation work tables

Innovations to improve Calandria Tube installation at Darlington

Whiteshell decommissioning: design & build

First-of-a-kind remotely controlled system to safely retrieve, sort, and package radioactive waste for remediation of CNL’s Whiteshell site

Whiteshell decommissioning: ISOT

Full-scale outdoor mock-up facility in Cambridge for Integrated System Operations Testing (ISOT) and operator training on the Whiteshell decommissioning equipment

Advanced Nuclear Materials Research Centre

Design, manufacture, and test of prefabricated structures, components and remotely controlled systems for CNL’s state-of-the-art, multi-unit Hot Cell facility in Chalk River for R&D on radioactive materials and used fuel

ROMA arm demo

Strength in collaboration

We believe that collaboration drives innovation. By working closely with utilities, nuclear operators, engineering partners, and technology suppliers, we deliver integrated automation systems that address the evolving needs of the nuclear energy industry.

Our collaborative strengths include:

- Artificial intelligence: Predictive maintenance and performance optimization.

- Industrial robotics: Collaborative robots (cobots) that enhance safety and efficiency.

- Digital Twins: Real-time simulations for design and training.

- Custom tools: Automated flaw detection, document management, and non-destructive examination (NDE) analysis.

- Sustainability: Embedded Industry 4.0 practices for cleaner, smarter operations.

Eclipse Omniverse demo

Case study

Turnkey solution offers design, build, test, transport, & assembly

The ask from the client was for a system that could safely retrieve, sort and package nuclear waste. Eclipse Automation stepped up, took over the design and provided a comprehensive and innovative solution that met the needs and more.

Contact with our nuclear experts

Download our nuclear automation brochure

Click to view our nuclear industries brochure in PDF format.

Powered by local expertise and global experience